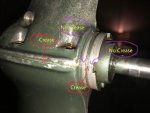

I am currently rebuilding a 67 Johnson 6hp and am having a problem separating the upper and lower half of the gearcase so I can access the gears, prop shaft, etc. The service manual, seloc manual, and various youtube videos I have found seem to treat separated the find from the upper portion of the gearcase as a trivial matter, however, I am having trouble separating the two and am trying to be careful not to cause any damage. I removed the six screws that connect the two as well as the pivot pin, but no luck. There must be something I am missing, but for the life of me I can figure it out. Any suggestions or help is much appreciated!

Thanks,

Billy

Thanks,

Billy