New to the forum here, but I have read lots of good info. here so I figured I'd see if I can get any help with an issue I am having.

I recently purchased an old mirrocraft 14' with a Johnson 9.9 long shaft style outboard (it has the extension housing).

I was told by the previous owner to replace the impeller since it had not been done recently.

I removed the lower unit and when pulling the water pump off the shaft, the shaft pulled out from the gear housing. I'm assuming there is nothing that holds this in place, otherwise it would not have pulled out?

I then replaced the water pump, impeller and got it installed with no issues.

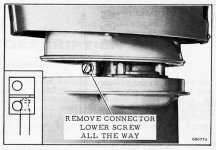

The problem I am having now is I can get the lower unit all the way up against the upper. It seems like it has something to do with the shaft not sliding up far enough, but I suppose it could also be the copper tube not getting into the rubber grommet. Should this require a great amount of force to get it all the way up? Is there a trick to getting this back together that I am missing?

Thanks in advance for any help..

I recently purchased an old mirrocraft 14' with a Johnson 9.9 long shaft style outboard (it has the extension housing).

I was told by the previous owner to replace the impeller since it had not been done recently.

I removed the lower unit and when pulling the water pump off the shaft, the shaft pulled out from the gear housing. I'm assuming there is nothing that holds this in place, otherwise it would not have pulled out?

I then replaced the water pump, impeller and got it installed with no issues.

The problem I am having now is I can get the lower unit all the way up against the upper. It seems like it has something to do with the shaft not sliding up far enough, but I suppose it could also be the copper tube not getting into the rubber grommet. Should this require a great amount of force to get it all the way up? Is there a trick to getting this back together that I am missing?

Thanks in advance for any help..