IslandExplorer

Petty Officer 1st Class

- Joined

- Oct 21, 2019

- Messages

- 370

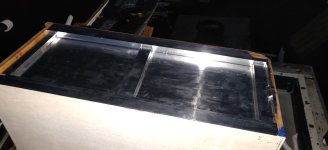

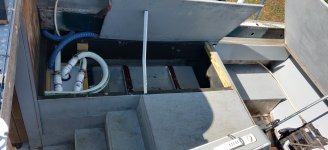

Oh, it's definitely getting painted, I just haven't had time to paint (or pre paint) things. This project needs to be operational asap and has taken longer than expected so I'm going to be forging ahead relentlessly. Boat is going in the water, one way or another. Liberty ship mode. Ideally I'd love to seal with epoxy but I haven't the budget for it unfortunately, will be lucky if I can even put gas in it at this point! LOL So far I've been using my go-to paint: Rustoleum alkyd enamel and the grippy porch/patio paint. Been impressed with Rustoleum products for many years, tough stuff! Another big thing is it dries super fast which has helped since I'm in New Seattle lolI would for sure suggest sealing or even glass over that plywood to give it some extra resistance to water/moisture.

Some guys were using outdoor rated wood sealer to coat the wood to keep costs down.

I went with West Marine epoxy, stuff is super strong and easy to work with.

but it's not cheap.

I went as far as to predrill my holes a little too large, then seal those holes up with a few coats of epoxy to ensure a long life.

a minimum of two coats was my general rule, and i used wax paper to help hold the epoxy onto the surface so I could do both sides at once.

Never tried wax paper to do both sides with epoxy, sounds pretty slick!