Nice work!

I looked thru my OMC Cobra shop manual for the torque spec on the nuts that hold the coupler on the studs in the flywheel and they give 40-45 ft lbs.

You can see 3 advantages that the Ford engines had over the GM engines...

1) oil filter up front don't need the complication of a remote oil filter mount

2) starter bolts go in parallel to the block not in the bottom, easier than on GM

3) distributor is up front

Yep that rubber hose on the bell housing is just to drain water out, mine has it too, not sure why they felt it was needed.

Thanks. I didn't use a torque wrench but it felt like I tightened the coupler / flywheel nuts to around 45ft/lbs.

I haven't had time to do much with the boat since my last post. Around the time of my last post the weather was really changeable, I was getting fed up of starting some work on the engine in good weather only for it to start raining heavily. Then I thought I'll just put the bimini / weathe cover on then I can work inside and stay dry (and the engine and carpet stay dry) even if it rains. Heh, I'd forgotten which way the poles fitted for the bimini and it took me over an hour to put it up. There was always 1 pole missing, a length of around 2.5ft 22mm OD x 1.5mm wall thickness polished stainless tube which I've bought but not yet fitted. There were also a few pins missing which I've bought and have fitted (except for the pins for the missing tube).

Did a bit of head scratching trying to work out how the alternator and tensioner bracket fitted, watched a Youtube video showing a guy changing the V belts and found the bracket fits to the front of the water pump. I had already fitted the WP using new stainless bolts so I needed to remove those 2 WP bolts I'd already fitted to fit a couple of longer bolts that would reach through the tensioner and WP. Today I visited a local bolts specialist firm who gave me an assortment of bolts and I got the bracket fitted.

Having fitted the alternator bracket I decided to change the thermostat. Problem is although the thermostat housing is OK the cast iron elbow it bolts to had already been repaired where one of the bolt holes (for the longer bolt) had broken, there's supposed to be a hole there but there's just half a hole with the outer part broken off. Someone had tried to repair it in the past by welding a nut to the cast elbow but the weld broke when I removed the housing. There's still half the hole remaining so it looks like there's enough material for a nut to pull on and I should be able to effect a fix but I'd probably buy another elbow if I could find one. I can easily buy a new housing but seemingly not the elbow. I've ordered mixed wire wheels to attach to the drill / dremmel to clean up the inside of the housing before I fit the new thermostat in it, also ordered some JB weld in case it helps fix the mouting hole on the elbow. I realise it's hard to advise without seeing pics (and I should have taken some to post here) but would appreciate any advise on how to effect a fix of the broken bolt hole in the elbow..? The design of the way the thermostat fits doesn't look very secure just held in with a rubber O ring, in the video I watched the guy helps make sure it seals and is secured by using some sealant under the 'stat and around the O ring, any advice on that?

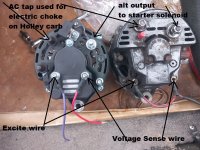

I think my next question (after the one above) will be on how to wire the alternator. The alternator I removed worked fine but I think I broke it during removal when a connector sticking out the back of the alternator worked loose when I unscrewed the nut that secured a wiring connector to the back of it... so I bought a new one. The new one fits OK and is apparently the correct one for the boat but the wiring connectors are a bit different. Again I should've taken pics of the old and the new before asking for advice - I'll post pics when I've been in the boat again.

I have new exhaust flappers to fit but it looks like they won't seal the exhaust from water coming up the wrong way much better than the existing flappers, doesn't look like the shape will properly seal the exhaust downpipes because they'll leave some room at the side of the flappers for water to get past. Also there's no spring etc to keep the flappers closed... Is this how they're supposed to be? I understand that later models deleted the flappers, but I know how low my boat sits at the rear end in the water and the top of the risers doesn't seem that far above the water line, is it worth fitting the new flappers?

Seems like I'm getting pretty close to finishing the install now, could probably get it all done in a few hours if it wasn't for the few problems/questions about the broken hole in the elbow that the thermostat housing bolts to, alternator wiring, etc.

Just realised the firm I visited today (that gave me the bolts) probably sold big screwdrivers... I still need a big screwdriver to drain/refill the trans fluid, I already have the fluid. Knew there was something I forgot!