Franco_boater

Petty Officer 2nd Class

- Joined

- Nov 2, 2021

- Messages

- 112

Ciao friends,

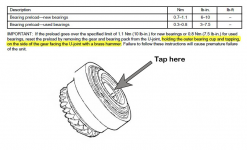

I will need to change upper oil seal there is a leak there, I found information that yoke needs to be replaced, thats OK i have ordered spanner BUT...

if all the upper gearcase will be removed its smart to change yoke seal and oring.

I have dial torque wrench for that and thats ok but what I dont know do I need to separate the bearings or not? I will only replace seal and o ring I am afraid of that because I have only bearing separator in my garage, no press...

I will need to change upper oil seal there is a leak there, I found information that yoke needs to be replaced, thats OK i have ordered spanner BUT...

if all the upper gearcase will be removed its smart to change yoke seal and oring.

I have dial torque wrench for that and thats ok but what I dont know do I need to separate the bearings or not? I will only replace seal and o ring I am afraid of that because I have only bearing separator in my garage, no press...