Hi All,

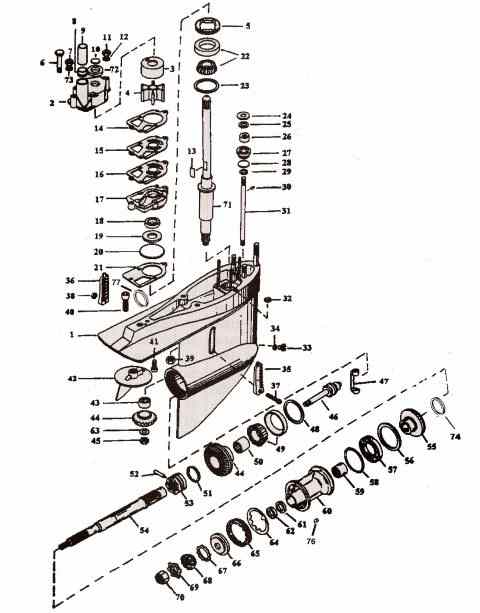

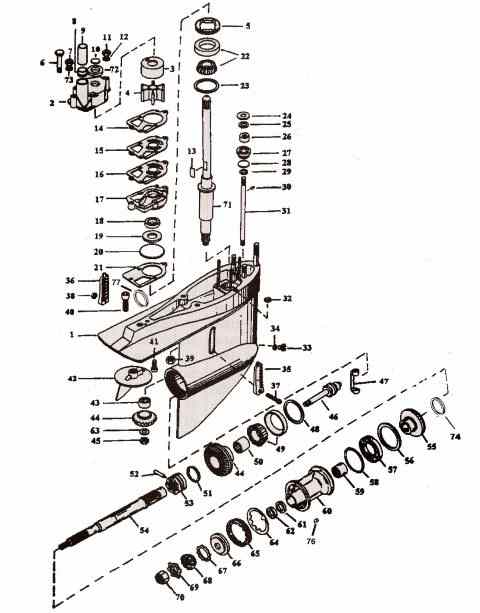

I'm in the process of replacing the propeller shaft seals & oring on my alpha one gen 1. Had a nightmare of a time getting the bearing carrier out, had to drill out the ring, soaked the bearing carrier for days, heat and lots of tension from the puller finally freed it. Now the problem is the thrust ring and thus reverse gear are still inside the housing. I'm at a loss for how to get them out, there doesn't seem to be any great way to pull that ring out. For reference, I'm talking part #56/55 on this diagram:

Anyone have any ideas before I hope a marina can help me out?

Thanks!

Kip

I'm in the process of replacing the propeller shaft seals & oring on my alpha one gen 1. Had a nightmare of a time getting the bearing carrier out, had to drill out the ring, soaked the bearing carrier for days, heat and lots of tension from the puller finally freed it. Now the problem is the thrust ring and thus reverse gear are still inside the housing. I'm at a loss for how to get them out, there doesn't seem to be any great way to pull that ring out. For reference, I'm talking part #56/55 on this diagram:

Anyone have any ideas before I hope a marina can help me out?

Thanks!

Kip