stantonxr7

Cadet

- Joined

- Oct 7, 2015

- Messages

- 12

What is a good way to section in a new section of a stringer to an old section of stringer?

I've cut out the bad part of the stringer which was from the transom forward about 50"

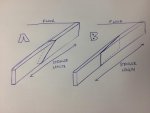

My current plan is to do something similar to shortening or lengthening of truck frames. My technique is to cut a vertical down half the height of the stringer, make a cross cut of a certain length (around 8") and then cut the rest of the way down the stringer. This makes a shape close to a "Z" that I would then match the profile to the new stringer section.

I would fasten the two pieces with gusset plates and fiberglass the whole works.

Is this acceptable? There's plenty of discussion on if the plywood stringers actually offer any strength to the hull or if they're there simply to create a beam shape for the fiberglass; that is in some viewpoints considered the strength of the hull. I've read about scarf beveling and don't think this an option for me.

Hoping to do this tonight and would appreciate some quick feedback. Thanks.

I've cut out the bad part of the stringer which was from the transom forward about 50"

My current plan is to do something similar to shortening or lengthening of truck frames. My technique is to cut a vertical down half the height of the stringer, make a cross cut of a certain length (around 8") and then cut the rest of the way down the stringer. This makes a shape close to a "Z" that I would then match the profile to the new stringer section.

I would fasten the two pieces with gusset plates and fiberglass the whole works.

Is this acceptable? There's plenty of discussion on if the plywood stringers actually offer any strength to the hull or if they're there simply to create a beam shape for the fiberglass; that is in some viewpoints considered the strength of the hull. I've read about scarf beveling and don't think this an option for me.

Hoping to do this tonight and would appreciate some quick feedback. Thanks.