Jacob Rogers

Cadet

- Joined

- Sep 19, 2024

- Messages

- 8

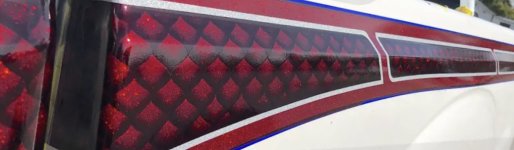

Hey guys new here! I have a question I can’t find an answer too. So my motor bit the dust, so this winter I’ll be saving up for another motor. In the mean time I’m going to be changing the color of my boat from dark green to red with metal flake, I already have the process and materials I need to re do the gelcoat. My question is how can I get this design with my gelcoat, I also have an airbrush which I would be using to make the pattern. Is it possible? If so how and when would you airbrush the design in? After the gelcoat with metal flake cured? Or gelcoat with metal flake without wax airbrush the black on when the Gelcoat gets tacky, then 4-5 coats of clear gel last being with wax?Thanks in advance!

Attachments

Last edited: