I was browsing CL last night when a strange ad for a 17' boat popped up. Nothing in the ad but 17alum. boat, free.

I shot the guy an email and he called me this afternoon.

The boat is a one owner, but badly neglected.

I went to see the thing, it was parked in a field, and it had apparently been there for decades.

The best way to describe the interior is a combination between mud and mulch.

There were 3ft of wet leaves in the boat, the seats had melted into a pile of brittle vinyl and rotten plywood.

I climbed into the boat and looked around but the deck is rotted completely away, not so much as a single strip of hard plywood left. Its a 1973 16ft Starcraft SS.

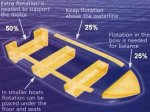

What got my attention was that I kept finding concrete blocks laying about the boat. When I asked what they were for he told me his buddy told him that a boat needs ballast to float. I though he was joking at first but he went on to explain that if you put enough weight in the boat it can't capsize. After that comment I just backed my truck and trailer up to the boat and winched it on, the trailer had no tires left, about 2 inches of the rims and most of the trailer was rusted away but it was still holding the boat.

When I got home, I took a grain shovel and started to clean out the boat a bit, what I found was 16 concrete blocks, four under the splash tray, two under each side console, 6 up in the bow, and two just laying out in the middle of the deck, which i think may have been in the lower seat boxes but at this point I can't tell. Most of the deck came out with a shovel and a hose. What I have left is white polystyrene foam blocks, most of which all seem to be ok and not water logged somehow. There was also four spare wheels for the trailer, two 15" car rims, four plastic 6 gallon fuel tanks full of what used to be gas, and one Evinrude metal fuel can rusted to the point where the bottom fell out. This probably explains the melted section of foam in the rear corner.

The things people do to their boats never ceases to amaze me.

At this point I'm not sure what I'll do with it but the hull itself is super clean, the bottom of the boat still shines. It certainly holds water, it drained for four hours before it stopped dripping out the drain hole.

I'm sort of thinking of making it an open boat, maybe with just one console. No railing, no windshield, but that's just a though. I've got a good 110hp Evinrude that needs a home but these are only rated at 85hp, but I think I might give it a try anyway. I had one of these with a 50hp, another with a 75hp, and my last one had a 90hp and that by far was the right motor.

I shot the guy an email and he called me this afternoon.

The boat is a one owner, but badly neglected.

I went to see the thing, it was parked in a field, and it had apparently been there for decades.

The best way to describe the interior is a combination between mud and mulch.

There were 3ft of wet leaves in the boat, the seats had melted into a pile of brittle vinyl and rotten plywood.

I climbed into the boat and looked around but the deck is rotted completely away, not so much as a single strip of hard plywood left. Its a 1973 16ft Starcraft SS.

What got my attention was that I kept finding concrete blocks laying about the boat. When I asked what they were for he told me his buddy told him that a boat needs ballast to float. I though he was joking at first but he went on to explain that if you put enough weight in the boat it can't capsize. After that comment I just backed my truck and trailer up to the boat and winched it on, the trailer had no tires left, about 2 inches of the rims and most of the trailer was rusted away but it was still holding the boat.

When I got home, I took a grain shovel and started to clean out the boat a bit, what I found was 16 concrete blocks, four under the splash tray, two under each side console, 6 up in the bow, and two just laying out in the middle of the deck, which i think may have been in the lower seat boxes but at this point I can't tell. Most of the deck came out with a shovel and a hose. What I have left is white polystyrene foam blocks, most of which all seem to be ok and not water logged somehow. There was also four spare wheels for the trailer, two 15" car rims, four plastic 6 gallon fuel tanks full of what used to be gas, and one Evinrude metal fuel can rusted to the point where the bottom fell out. This probably explains the melted section of foam in the rear corner.

The things people do to their boats never ceases to amaze me.

At this point I'm not sure what I'll do with it but the hull itself is super clean, the bottom of the boat still shines. It certainly holds water, it drained for four hours before it stopped dripping out the drain hole.

I'm sort of thinking of making it an open boat, maybe with just one console. No railing, no windshield, but that's just a though. I've got a good 110hp Evinrude that needs a home but these are only rated at 85hp, but I think I might give it a try anyway. I had one of these with a 50hp, another with a 75hp, and my last one had a 90hp and that by far was the right motor.