usernamewastaken

Cadet

- Joined

- Aug 2, 2020

- Messages

- 7

This started off intermittent. Long runs at WOT and when pulled back to idle RPM’s were 1200 at first. A coupe of times it went 2500-2800. Turning off and waiting for restart and it would be good for until WOT again. I checked wires to ISC and found the green/black didn’t have continuity. Repaired that.

This is no longer intermittent. It does it all the time now at start up. I was thinking back through attempts to trouble shoot. When I was looking for loose or distressed wire I was jiggling the harness near the ISC. I reached down and bumped the throttle arm up a bit and it took off up to 2800 and has stayed in that range since. Throttle valve is not loose or missing screws. TPS voltage is in range for idle. Placing my finger over the inlet for the ISC kills the motor. If I take it easy when I put my finger over the valve I can get it to idle at 400 or so. So it’s not leaking air any where else.

I have posted this elsewhere and I’m pasting where I’m at now. I have replaced the ISC valve and installed a used ECM. No changes to below after.

“1100 rpm for a few seconds, ramps up to 2500-2800. Clearly sucking air in the ISC valve.

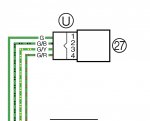

Engine off key on voltage at ISC connector

G/y. 12.47

G/b 8.53

G/r 8.44

Same voltages when tested at green ISC connector wire and engine ground

Engine running

G/y 14.62

G/b 8.65

G/r 8.56

Execute stationary test of ISC and I can hear it doing its thing.

Execute ISC valve 100% open in active test. Engine running in neutral at 2800, As it increases in % open the ISC actually closes and eventually kills the engine at 100% open. Obviously activating in reverse.......

Check voltage at ISC connector during ISC valve active test and voltage drops to

G/y drops to 7.5

G/b drops to 7.26

G/r drops to 7.24

Disconnect ISC valve and engine will idle at 1100 all day long. Of course Im not sure what all this means other than the ISC valve appears to be working in reverse”

This is no longer intermittent. It does it all the time now at start up. I was thinking back through attempts to trouble shoot. When I was looking for loose or distressed wire I was jiggling the harness near the ISC. I reached down and bumped the throttle arm up a bit and it took off up to 2800 and has stayed in that range since. Throttle valve is not loose or missing screws. TPS voltage is in range for idle. Placing my finger over the inlet for the ISC kills the motor. If I take it easy when I put my finger over the valve I can get it to idle at 400 or so. So it’s not leaking air any where else.

I have posted this elsewhere and I’m pasting where I’m at now. I have replaced the ISC valve and installed a used ECM. No changes to below after.

“1100 rpm for a few seconds, ramps up to 2500-2800. Clearly sucking air in the ISC valve.

Engine off key on voltage at ISC connector

G/y. 12.47

G/b 8.53

G/r 8.44

Same voltages when tested at green ISC connector wire and engine ground

Engine running

G/y 14.62

G/b 8.65

G/r 8.56

Execute stationary test of ISC and I can hear it doing its thing.

Execute ISC valve 100% open in active test. Engine running in neutral at 2800, As it increases in % open the ISC actually closes and eventually kills the engine at 100% open. Obviously activating in reverse.......

Check voltage at ISC connector during ISC valve active test and voltage drops to

G/y drops to 7.5

G/b drops to 7.26

G/r drops to 7.24

Disconnect ISC valve and engine will idle at 1100 all day long. Of course Im not sure what all this means other than the ISC valve appears to be working in reverse”