Good day, I have a 78' AQ120B that I got from someone who was letting the boat mold in a backyard (for 20 years) that I'm having a bit of an issue with. I just replaced the timing belt and now the distributor will not line up. Here's the skinny:

Timing belt was a Volvo belt with marks

Old belt was trash and rotted/missing teeth, no idea if the motor ran before

Lined up all of the timing marks on the engine

Installed the belt and the timing marks on the belt lined up with the marks on the cogs

Put the engine back together

Did other work (cleaned out carb, etc.)

Fired up the engine and it wouldn't run, seemed like a timing issue

Rotated the distributor as far as it would go advanced and the engine tried to fire

Removed distributor hold down bolt and rotated it a bit more, engine fired and ran

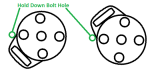

Here's the conundrum. No matter what I do the engine will only run if the distributor is outside of the hold down bolt range. I can pull the dist and move the rotor back, but then the distributor has to be rotated too far back to get the correct timing for the hold down bolt to fit. If I move it forward one gear tooth it sits too far forward. I've checked the timing marks several times and tried rotating the distributor drive shaft one tooth either direction. I also tried moving the distributor and then moving the wire positions to the next tower over. I haven't found any combination of distributor position to wire position to shaft position that will allow me to put in the hold down bolt with the engine at TDC. Does anyone have any ideas?

Timing belt was a Volvo belt with marks

Old belt was trash and rotted/missing teeth, no idea if the motor ran before

Lined up all of the timing marks on the engine

Installed the belt and the timing marks on the belt lined up with the marks on the cogs

Put the engine back together

Did other work (cleaned out carb, etc.)

Fired up the engine and it wouldn't run, seemed like a timing issue

Rotated the distributor as far as it would go advanced and the engine tried to fire

Removed distributor hold down bolt and rotated it a bit more, engine fired and ran

Here's the conundrum. No matter what I do the engine will only run if the distributor is outside of the hold down bolt range. I can pull the dist and move the rotor back, but then the distributor has to be rotated too far back to get the correct timing for the hold down bolt to fit. If I move it forward one gear tooth it sits too far forward. I've checked the timing marks several times and tried rotating the distributor drive shaft one tooth either direction. I also tried moving the distributor and then moving the wire positions to the next tower over. I haven't found any combination of distributor position to wire position to shaft position that will allow me to put in the hold down bolt with the engine at TDC. Does anyone have any ideas?