Silverbullet555

Chief Petty Officer

- Joined

- Mar 13, 2011

- Messages

- 621

2002 8.1gi-b

450 hours

port side manifolds run 20-30 degrees hotter than starboard. This happens if bost is level or not; in the water or on the muffs.

I know some will say this is normal, but this a new issue and when something new comes along then something changed.

Engine does not overheat. Issue is in the flow that goes to the manifolds and risers.

Problem arose 2 years ago. I was sick last year so I didn't work on it.

Compression test is fine.

Leakdown test is fine

Manifolds and risers have been checked

Oil cooler has been backflushed

Raw water pump replaced.

Used clear hose to observe water flow. Noticed water flow to port side much less than starboard. Put equal length hoses in the system and swapped sides. The low flow switches sides as does the higher temps.

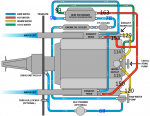

To me this indicates the issue is NOT in the cooling system after the thermostat housing. It has to be somewhere upstream of that. Possibly the thermostat housing though I have visually checked it. The other possibility is that there is some kind of blockage which is simply reducing the flow and pressure enough that one side is getting starved

450 hours

port side manifolds run 20-30 degrees hotter than starboard. This happens if bost is level or not; in the water or on the muffs.

I know some will say this is normal, but this a new issue and when something new comes along then something changed.

Engine does not overheat. Issue is in the flow that goes to the manifolds and risers.

Problem arose 2 years ago. I was sick last year so I didn't work on it.

Compression test is fine.

Leakdown test is fine

Manifolds and risers have been checked

Oil cooler has been backflushed

Raw water pump replaced.

Used clear hose to observe water flow. Noticed water flow to port side much less than starboard. Put equal length hoses in the system and swapped sides. The low flow switches sides as does the higher temps.

To me this indicates the issue is NOT in the cooling system after the thermostat housing. It has to be somewhere upstream of that. Possibly the thermostat housing though I have visually checked it. The other possibility is that there is some kind of blockage which is simply reducing the flow and pressure enough that one side is getting starved