merc120_81

Petty Officer 3rd Class

- Joined

- Jun 20, 2011

- Messages

- 92

After gimble bearing replacement, just can't seem to get to align. seeing some off left/right. and have some motion on the port rear side of the motor when removing allignment tool between tweaks/tests of allignment.

I commented on another post, BT advised, to try loosening rear mounts and front lags, adjusting the engine and re-torque. I am going to give that a shot, but if that fails I want to get the parts on order ASAP.

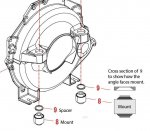

I am having an issue figuring out correct part numbers for rear mounts on the following:

1981 120 s/n 5828080 engine

Transom plate s/n 5776312

Stern Drive 5804180

I think I need bolt kit sierra

bolt kit

18-2140

Mounts/bushings

18-2193

-I am concerned that these maybe too "new" 1983/bravo not alpha/pre-alpha mc1?

I commented on another post, BT advised, to try loosening rear mounts and front lags, adjusting the engine and re-torque. I am going to give that a shot, but if that fails I want to get the parts on order ASAP.

I am having an issue figuring out correct part numbers for rear mounts on the following:

1981 120 s/n 5828080 engine

Transom plate s/n 5776312

Stern Drive 5804180

I think I need bolt kit sierra

bolt kit

18-2140

Mounts/bushings

18-2193

-I am concerned that these maybe too "new" 1983/bravo not alpha/pre-alpha mc1?