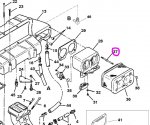

Does any one know how to remove the 4 studs that hold the throttle body and which appear after removing the flame arrestor on a 1997 Mercruiser 454 mag mpi? I have tried multi grips, a stud removing tool and also tried to lock two nuts together on the thread and undo the inner one. Nothing seems to work. They are either on very tight and I should use more force with the stud remover or there is some other trick I do not know about.

I am trying to get at the IAC valve, since I seem to have an idling problem.

I am trying to get at the IAC valve, since I seem to have an idling problem.