Hab

Petty Officer 2nd Class

- Joined

- Jul 4, 2017

- Messages

- 158

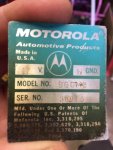

Im guessing wont be too many here interested in this but i thought id document my failures anyhow. I have (2) of these. Both have disintegrated wiring, and have not run for many years. Dad and I played with one a few years ago, trying to convert to a better or at least simpler ignition system, but got derailed when we started checking the electric shift gizmos.

Anyway, i got one of the amplifiers the other day and started to tear it up. I cut out the soft potting, and used soldering irons, picks, ans screwdrivers to remove the harder potting. Not sure if i can remove the PCB and rebuild but I'm going to attempt it anyway. I did manage to find and remove (5) screws securing the board to the outer case. hopefully i can remove the remaining potting bonding it to the case this evening.

Anyway, i got one of the amplifiers the other day and started to tear it up. I cut out the soft potting, and used soldering irons, picks, ans screwdrivers to remove the harder potting. Not sure if i can remove the PCB and rebuild but I'm going to attempt it anyway. I did manage to find and remove (5) screws securing the board to the outer case. hopefully i can remove the remaining potting bonding it to the case this evening.