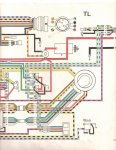

What is the function of Sensor Coil wire “A”, the blue wire? The sensor coil is a $200+ item, maybe I can do without this function and labor? It looks like it is related to the S.L.O.W system. Attached is the wiring diagram (I can only copy in halves.).

Here are the results of the tests the manual calls for the Sensor Coil, using the Ohmmeter and using a Peak Voltage Tester. Terminal “A” failed on both:

Peak Voltage Tests with Digital multimeter and ESI Model 640 DVA Adapter

Sensor Coil Test pg 3-32 - #11 Ground Test – ABCD Passed

Sensor Coil Test pg 3-32 - #11 Output Test – A 0.00, B 1.5v, C 1.78v (spec 0.3v or higher) “A” Failed

Manual says solution is – check condition of wiring, if wiring is good, go to ohmmeter test ( “A” also failed in ohmmeter test)

Ohmmeter Tests

Sensor Coil Test pg 3-33 - #13 - “A” Blue wire Failed OL reading, terminals B&C 12 ohm Passed (all must be 11+-3 ohm)

Sensor Coil Test pg 3-33 - #14 – ABCD Passed no reading (spec - no reading)

Here are the results of the tests the manual calls for the Sensor Coil, using the Ohmmeter and using a Peak Voltage Tester. Terminal “A” failed on both:

Peak Voltage Tests with Digital multimeter and ESI Model 640 DVA Adapter

Sensor Coil Test pg 3-32 - #11 Ground Test – ABCD Passed

Sensor Coil Test pg 3-32 - #11 Output Test – A 0.00, B 1.5v, C 1.78v (spec 0.3v or higher) “A” Failed

Manual says solution is – check condition of wiring, if wiring is good, go to ohmmeter test ( “A” also failed in ohmmeter test)

Ohmmeter Tests

Sensor Coil Test pg 3-33 - #13 - “A” Blue wire Failed OL reading, terminals B&C 12 ohm Passed (all must be 11+-3 ohm)

Sensor Coil Test pg 3-33 - #14 – ABCD Passed no reading (spec - no reading)

Attachments

Last edited: