jimmbo

Supreme Mariner

- Joined

- May 24, 2004

- Messages

- 12,961

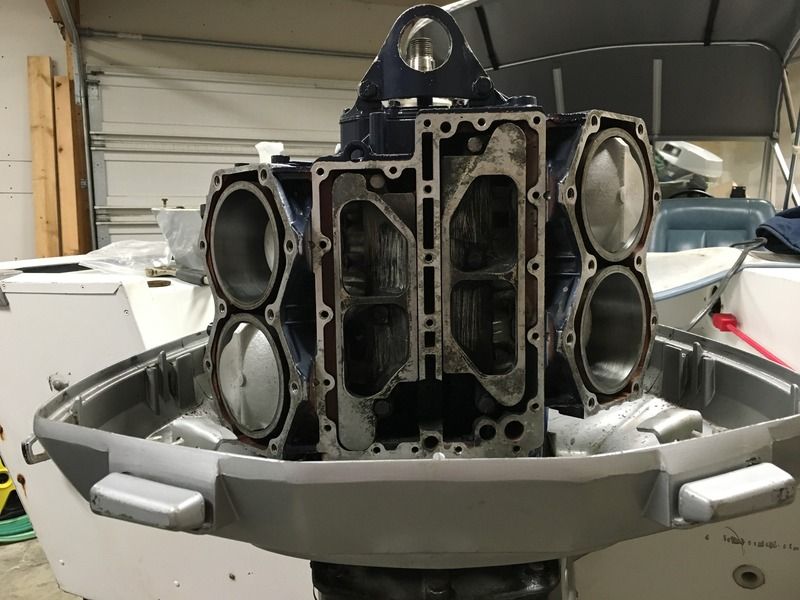

When the crankcase is under compression, the pressure pushes the puddled fuel into the lines and subsequent pressure pulses continue to move along, either into bearings higher up, or into the intake passages of other cylinders which intake ports are opening. The check valves prevent backflow when the crankcase is under negative pressure