topgun3690

Ensign

- Joined

- May 7, 2019

- Messages

- 973

Recently replaced the o-rings in my tilt cylinder as it was leaking around the top. The leaking stopped but now I have a leakdown problem. When fully raised the motor slowly comes down, takes about 15-20 minutes.

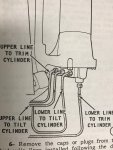

I tried the tests mentioned in the stickies. The first test was for the tilt cylinder. Disconnected and capped the line and plugged the valve body. The tilt came down just like before. The solution given by Jiggz was to rebuild or replace the tilt cylinder. Since I already rebuilt the tilt is it possible that the valvebody is causing the leakdown? My Chrysler manual had a test for the trim cylinder and it passed, never came down any. So my question is: Can a bad(leaking) valvebody make the tilt cylinder appear to be bad?

I tried the tests mentioned in the stickies. The first test was for the tilt cylinder. Disconnected and capped the line and plugged the valve body. The tilt came down just like before. The solution given by Jiggz was to rebuild or replace the tilt cylinder. Since I already rebuilt the tilt is it possible that the valvebody is causing the leakdown? My Chrysler manual had a test for the trim cylinder and it passed, never came down any. So my question is: Can a bad(leaking) valvebody make the tilt cylinder appear to be bad?