arriva2001

Seaman

- Joined

- Feb 15, 2015

- Messages

- 62

This weekend, I had my boat out, and all was working well until I had engine tilted all the way up to install the trailer bracket. When I went to lower it down, I heard a hiss, the motor didn't do anything...and then all of a sudden, smoke was pouring out of the engine cowling. I opened it up with fire extinguisher at the ready, and what has happened is most of the insulation off the wire leading to the trim/tilt motor has melted, along with insulation on red, blue, and green wires on the Trim/Tilt relays. Thankfully I didn't need the fire extinguisher--all this wiring is SO close to the carburetors and fuel!!

I closely inspected the wiring leading to the pump that still had some insulation left, and from what I can tell, the insulation looks like it was dry rotted/cracked, and it shorted out--and the melting started right where the short started.

I have ordered a new wiring harness and will replace the wire leading to the pump with 100% new wires and heat shrink tubing.

My questions are:

1) do I need to look beyond this area under the motor compartment for melted wiring? Where do I need to trace back to to make sure there is not an issue? Could it go all the way up to the gear shift handle and switch? A lot of that wiring is going to be very difficult to get to, so I"m wondering if there are any tests I can perform or things to look for to see that it stopped at a certain point. I was hoping a fuse or something would isolate this problem. (Next question)

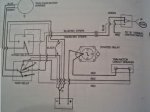

2) Is there any sort of a fuse or circuit breaker in this system that should have tripped? I am not all that familiar with electronics, but I thought the whole point of the circuit breaker/fuses was to prevent things like this from happening. If there is a fuse or circuit breaker, any idea where this is located in the engine compartment? I didn't try ANYTHING and unhooked the battery after this had happened, so no idea if anything else is toasted like starter or ignition, etc.

When I'm replacing things, is there an additional fuse I should put into place to prevent this from ever happening again?

For reference, my motor is a 1994 Force 150, model number H150412PE (I'm the original owner and no modifications have been made to this engine).

Thanks in advance for any help!

I closely inspected the wiring leading to the pump that still had some insulation left, and from what I can tell, the insulation looks like it was dry rotted/cracked, and it shorted out--and the melting started right where the short started.

I have ordered a new wiring harness and will replace the wire leading to the pump with 100% new wires and heat shrink tubing.

My questions are:

1) do I need to look beyond this area under the motor compartment for melted wiring? Where do I need to trace back to to make sure there is not an issue? Could it go all the way up to the gear shift handle and switch? A lot of that wiring is going to be very difficult to get to, so I"m wondering if there are any tests I can perform or things to look for to see that it stopped at a certain point. I was hoping a fuse or something would isolate this problem. (Next question)

2) Is there any sort of a fuse or circuit breaker in this system that should have tripped? I am not all that familiar with electronics, but I thought the whole point of the circuit breaker/fuses was to prevent things like this from happening. If there is a fuse or circuit breaker, any idea where this is located in the engine compartment? I didn't try ANYTHING and unhooked the battery after this had happened, so no idea if anything else is toasted like starter or ignition, etc.

When I'm replacing things, is there an additional fuse I should put into place to prevent this from ever happening again?

For reference, my motor is a 1994 Force 150, model number H150412PE (I'm the original owner and no modifications have been made to this engine).

Thanks in advance for any help!