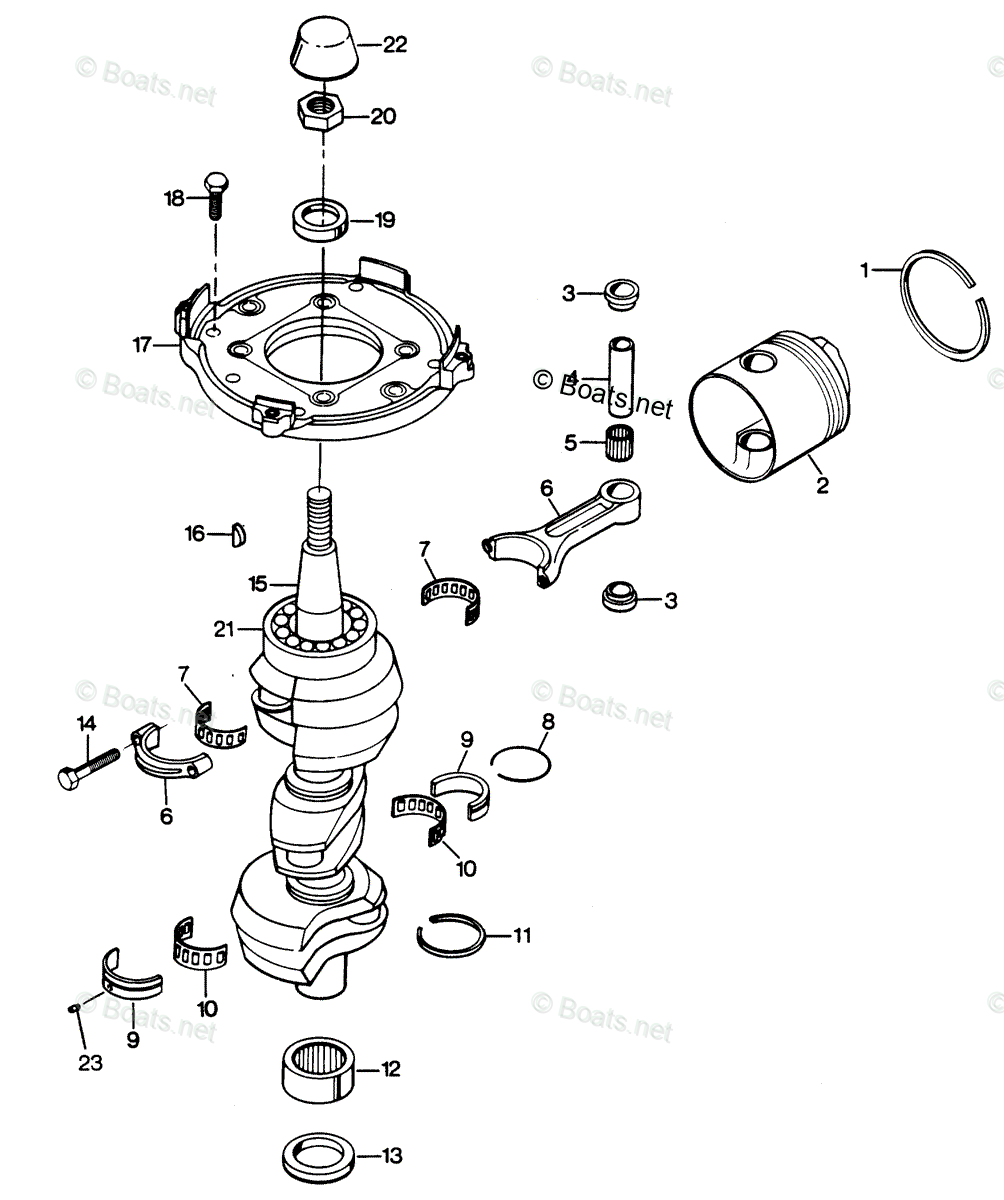

You can see the pin and hole on the bearing.

The pin fits in a corresponding hole on the block.

The pin's already pressed in and the bearing needs to be turned until

the holes line up.

If its not aligned the crank turns slowly or not at all.

Hi Jerryjerry,

I see what you meant (it's a similar to Merc. set up that have the valve-plates attached)

however these locating-pins are in the block

I noticed some scars/grooves in the block (intake side) this must be old and the reason the block has been opened before.

how else could that be there without any damage to the crank-bearings?

in the pic. (with the tip of the screwdriver pointing) initially I thought his this was a thrust-washer but upon closer inspection i saw it could not be one as it's actually on the crank & not in between.

after reading the tear down manual a little closer; I discovered there called crank-seals and need to be replaced.

I thinking these keep the pressures in the cylinder from escaping to the adjacent cylinders, finally my question;

If they are not cracked do they really need to be replaced?