MPrimeaux

Petty Officer 1st Class

- Joined

- May 10, 2019

- Messages

- 240

Hello all, I am restoring a 1957 Fleetform 14' fiberglass runabout with a 1963 Merc 650 on it. The boat is fitted with a cable and drum helm and I was planning on staying with the cable and drum. I have been doing my best to do my own research before asking a bunch of questions, but a little input would help. I have a couple of questions:

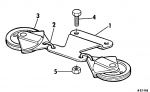

1. The only new tiller pulleys I seem to find have a hook instead of an eye.... is that ok? I realize they are made and sold like that, I was just wondering is someone could put my mind at ease with a tidbit of info on why they don't have eyes for something like a shackle.

2. I don't have the motor bracket for the Merc 650 that I put on it. The boat had a '57 35hp Evinrude Lark on it when I bought it and I have that bracket. Is it ok to simply build something out of say.... 3/16" - 1/4" stainless with a couple of holes drilled in it to bolt through the single hole in the front of the Merc?

3. I understand opinions vary, but I'm pretty sure I'm comfortable with the drum and cable steering. However the motor DOES have a hollow tilt tube for a push/pull.... modern.... Teleflex??? I'm a little confused on the correct terminology for a modern steering cable. I don't see where it would be cheaper to buy a new helm and cable, especially being I don't have the ball joint link to go from the cable to the motor either. Am I correct in assuming that it would be much cheaper and IF done correctly, safe to stay vintage with the drum and cable steering?

Any input will be appreciated.

Thanks everyone.

1. The only new tiller pulleys I seem to find have a hook instead of an eye.... is that ok? I realize they are made and sold like that, I was just wondering is someone could put my mind at ease with a tidbit of info on why they don't have eyes for something like a shackle.

2. I don't have the motor bracket for the Merc 650 that I put on it. The boat had a '57 35hp Evinrude Lark on it when I bought it and I have that bracket. Is it ok to simply build something out of say.... 3/16" - 1/4" stainless with a couple of holes drilled in it to bolt through the single hole in the front of the Merc?

3. I understand opinions vary, but I'm pretty sure I'm comfortable with the drum and cable steering. However the motor DOES have a hollow tilt tube for a push/pull.... modern.... Teleflex??? I'm a little confused on the correct terminology for a modern steering cable. I don't see where it would be cheaper to buy a new helm and cable, especially being I don't have the ball joint link to go from the cable to the motor either. Am I correct in assuming that it would be much cheaper and IF done correctly, safe to stay vintage with the drum and cable steering?

Any input will be appreciated.

Thanks everyone.