Grandad

Lieutenant Commander

- Joined

- Jun 7, 2011

- Messages

- 1,504

OK, I've lurked here long enough. It's time to tell my story over a few instalments to this thread. Much has been completed, but much more is to come. I have a 1972 21' Starcraft Holiday aluminum boat powered by a 120 HP Mercruiser I/O. I purchased it about 10 years ago, but it's been in the family since new. It was kinda tired when I got it, but had been properly maintained. The only shabby part was the sun damaged vinyl on the top decks and the yellowed plexiglass side and centre windshield panels. Sorry, no before pictures. My first task, replacing the plexi was easy and made a world of difference to the boat's appearance.

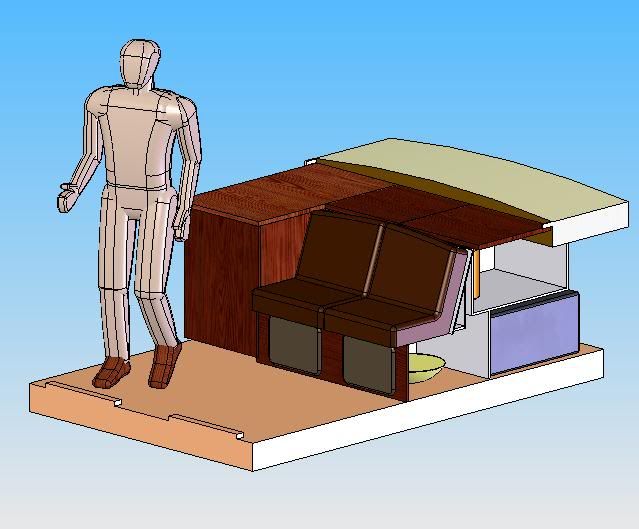

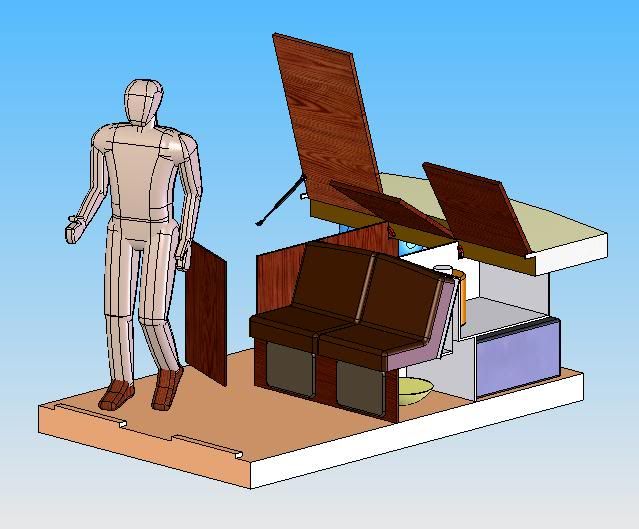

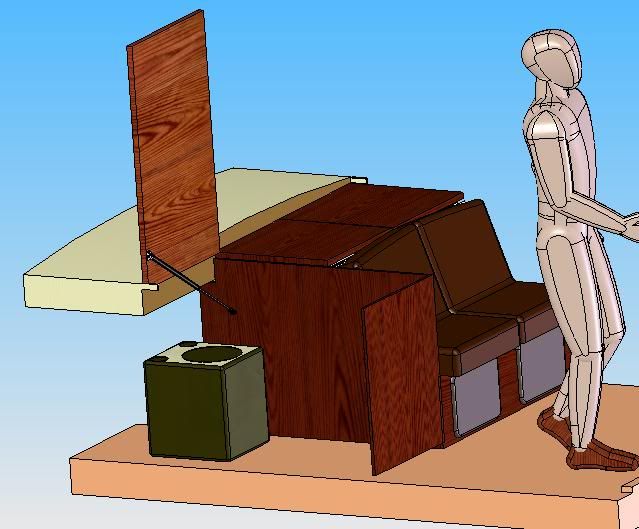

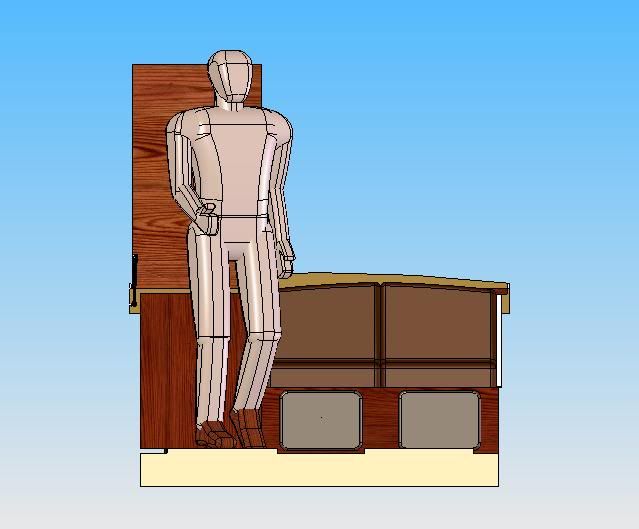

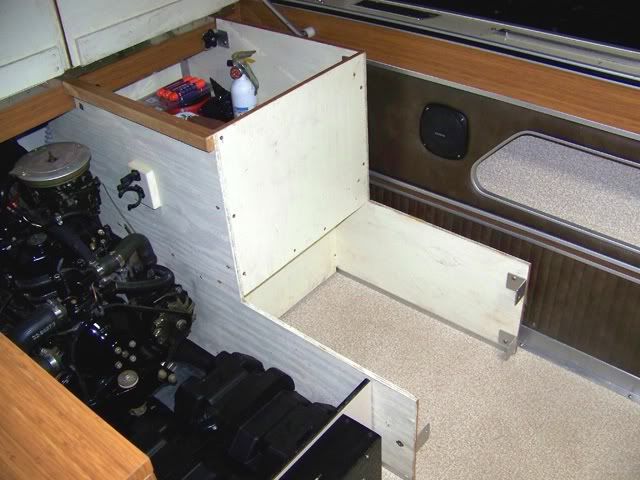

On the first trip out, it was evident that the sleeper style seats were too low. They had been replaced several years before and were in excellent condition, but no-one could see the horizon in front without straining up from a seated position. Using the original seat box as a pattern, I made new plywood boxes several inches higher and covered them with Formica wood grain laminate. With the tops of the seat backs now just at gunwale height, not only could we see a lot better, but the seats were more comfortable for our legs. There's more under seat storage space now too.

On the first trip out, it was evident that the sleeper style seats were too low. They had been replaced several years before and were in excellent condition, but no-one could see the horizon in front without straining up from a seated position. Using the original seat box as a pattern, I made new plywood boxes several inches higher and covered them with Formica wood grain laminate. With the tops of the seat backs now just at gunwale height, not only could we see a lot better, but the seats were more comfortable for our legs. There's more under seat storage space now too.

Last edited: