Update 10-17-2010

Update 10-17-2010

Check it out. Here is how we made out. First things first though, To all my buddies that helped me get this done last night,

Thanks. Without you guys I would not of been able to get this done to this point. We ran out of resin last nigth at 1:30am. The 1708 biax cloth really drinks it up. SOO far 6 gallons gone and need to order another 3 gallons to finish the transom portion of this job. So on hold till then!

We started by the evening by finishing the tabbing of the frame to the hull. Here is a pic.

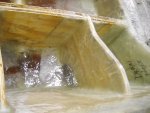

Then we layed 1708 biax sheets "one piece" over the stringers where there where no cross pieces. There tab the corners in the cross pieces with 1708. As seen here.

Then another layer of 1708 biax extending another 3-4" past previous layer. We where lucky no large bubbles between the layers. I do have a couple small bubbles, 4 total, 1" diameter. Here is a pick of the finished product from last night when we ran out of resin.

We set up a production line process. We took the wetting out of the 1708 biax with resin offline. I had one buddy cutting the 1708 pieces to the sizes I needed, another one mixing resin, and another two wetting out the 1708 biax on a piece of cardboard, and me laying it out in the hull after they where saturated. Total time last night 8 hrs per 5 guys. Used 7.5 yards of 1708 Biax. Need some more of this, probably 3 more yards to be safe.

I still have to glass in my transom gussets. I have about a 1/2gallon of resin left from pouring/combining all the little amounts from all the jugs. I'll try to get this done this afternoon. I will only use on layer of 1708 on the gussets and tab them in with 1708. The wood and one layer of 1708 biax fiberglass will be more that what Bayline used.

The plan for the next week.

1) Order the following

-3 gallons of resin

-3 yard of 1708 biax

2) Pour the floatation foam

3) Clean-up/sand the other areas that need glass'n still

-Tank support plate

-Top of floatation chamber

-Reinforcement of floatation chamber top

-Clean the garage again

-Vinyl gloves

4) Cut holes for stringer drains

5) Glass in the drain tubes

6) Finish gel coat repairs on bottom half

7) Buff the bottom of the hull

8) Vacuum/clean the the carpet in the front half

9) Make tarp support for the hull while it sits in the driveway

10) Make dolly support to moving the top half in and out of the garage

I'm a bit sore from twisting like a pretzel and a bit hung over from drinking to 3:30 in the morning. Tonight movie night with the kids. and abreak.

Enjoy

Jeff