gm280

Supreme Mariner

- Joined

- Jun 26, 2011

- Messages

- 14,590

This thread is going to show you how I built my live well from initial idea to reality. And while it isn't the gospel or final word on building live wells, it is merely how I built mine.

I am presently refurbishing a 1976 Tom Boy Boat (tri-hull design) that was totally trashed. And while it did have something resembling a live well, I wanted something a little better.

So I set out to come up with a simple design and started. My first attempt was to basically use a cooler. And that was for a few reasons. I could plug it in and plumb water to it and such to keep the fish (yea, like I really catch any) alive. And I went and bought a nice size cooler that I though would work. It was cheap and I thought my live well issues were covered. NOT SO FAST!

As I was drilling the cooler out to fit the spray bar and drain holes, I made the royal mistake to drill one hole from the outside in. :nono:

Never ever do that if you want the inside to stay intact. When the Forstner bit broke though the inside, it tore the inside plastic instantly. The plastic on the inside was a lot thinner then the plastic on the outside...a lot thinner too. So lesson learned there. If I would have started drilling from the inside first, it probably could have worked. Who know? :noidea:

You are probably wondering why I am posted these things. Just to let others know some of the things to watch for as they make their live well.

SOOOoooo I made a decision to built the live well from scratch being how the cooler was now useless. Yes I did try different glues and such, but it wasn't working to that idea and cooler was trashed...literally!

Now we can work on the real live well. eace:

eace:

First thing to do is figure out what size you need, not want. I say that because your wants are always larger then your needs. And remember one gallon of water weighs 8.34 pounds or 3.76 kgs. And those gallons add up real quick. So if you don't want to be carrying a lot of extra useless weight, size your live well design with some reasonable common sense.

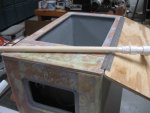

My design is 27 3/4" long by 15 3/4" wide by 12 3/4" deep. Yes I know those are unusual measurements. But I started with straight inches and when finished it was a bit larger. I used 3/8" thick "exterior" grade plywoods. But in all honesty, you could built it from 1/4" depending on what you finish it with. Ill explain as I go along.

So you can built your size to your needs. Mine is going into a stick steering boat similar to a Bass Pro pan-fish special setup. And I am going to use it as a seat as well for a third person or kid to sit on.

Here are a few pictures of my design and pictures thus far. More to come very soon.

I am presently refurbishing a 1976 Tom Boy Boat (tri-hull design) that was totally trashed. And while it did have something resembling a live well, I wanted something a little better.

So I set out to come up with a simple design and started. My first attempt was to basically use a cooler. And that was for a few reasons. I could plug it in and plumb water to it and such to keep the fish (yea, like I really catch any) alive. And I went and bought a nice size cooler that I though would work. It was cheap and I thought my live well issues were covered. NOT SO FAST!

As I was drilling the cooler out to fit the spray bar and drain holes, I made the royal mistake to drill one hole from the outside in. :nono:

Never ever do that if you want the inside to stay intact. When the Forstner bit broke though the inside, it tore the inside plastic instantly. The plastic on the inside was a lot thinner then the plastic on the outside...a lot thinner too. So lesson learned there. If I would have started drilling from the inside first, it probably could have worked. Who know? :noidea:

You are probably wondering why I am posted these things. Just to let others know some of the things to watch for as they make their live well.

SOOOoooo I made a decision to built the live well from scratch being how the cooler was now useless. Yes I did try different glues and such, but it wasn't working to that idea and cooler was trashed...literally!

Now we can work on the real live well.

First thing to do is figure out what size you need, not want. I say that because your wants are always larger then your needs. And remember one gallon of water weighs 8.34 pounds or 3.76 kgs. And those gallons add up real quick. So if you don't want to be carrying a lot of extra useless weight, size your live well design with some reasonable common sense.

My design is 27 3/4" long by 15 3/4" wide by 12 3/4" deep. Yes I know those are unusual measurements. But I started with straight inches and when finished it was a bit larger. I used 3/8" thick "exterior" grade plywoods. But in all honesty, you could built it from 1/4" depending on what you finish it with. Ill explain as I go along.

So you can built your size to your needs. Mine is going into a stick steering boat similar to a Bass Pro pan-fish special setup. And I am going to use it as a seat as well for a third person or kid to sit on.

Here are a few pictures of my design and pictures thus far. More to come very soon.

Attachments

Last edited: