So I would like to add a swim platform to my boat over the winter. Most places want over $2k (which I am sure is worth it) but I do not have the funds to pay for it. Nobody offers a platform for my boat, and would need me to take all the measurements for them to make one anyway, so I figure I could do it myself with the measurements. I have worked with wood/fiberglass many times, so I am not too worried about that part.

The boat is a 1995 Century Arabian 24. The built-in swim platform is only 17 1/2'' wide, and when when we tie up to our regulars on the lake it is a large step from our boat to theirs. I would like to add about 24'' from the center of the current platform, which would add roughly 29'' on each side, if I make it a straight edge across the back. I would make it lay over the current platform, and extend out an extra 24'' from the center.

I would probably use 3/8'' plywood (maybe treated?) as the base and then use something underneath, like 2x4s to form a frame/edge for the part that extends off the boat. The I would add a few layers of fiberglass, sand it smooth and gelcoat it afterwards. Currently my ladder just folds/flips up on top of the swim platform and I would like to add a ladder (4 step if possible) that stores under the new swim platform so it is out of the way when not in use.

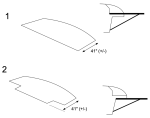

As for bracing, that is where it gets tricky (for me anyway.) I could add two straight braces from the swim platform to the transom towards the center, away from the outdrive. But I am not sure how I would brace the side edges. I am not sure what they are called, but my boat has 2 compartments in the rear that stick out form the transom, thats where my batteries are installed. I don't think I would be able to run a straight brace from the swim platform to the transom itself. I could maybe run the braces from the platform to these 2 compartments though.

When it is all finished I would probably add something like Seadek to it.

I have searched online and haven't really found much info on doing something like this. Except for one other guy on this forum but he is working on a larger scale (and budget!) than I could do.

The boat is a 1995 Century Arabian 24. The built-in swim platform is only 17 1/2'' wide, and when when we tie up to our regulars on the lake it is a large step from our boat to theirs. I would like to add about 24'' from the center of the current platform, which would add roughly 29'' on each side, if I make it a straight edge across the back. I would make it lay over the current platform, and extend out an extra 24'' from the center.

I would probably use 3/8'' plywood (maybe treated?) as the base and then use something underneath, like 2x4s to form a frame/edge for the part that extends off the boat. The I would add a few layers of fiberglass, sand it smooth and gelcoat it afterwards. Currently my ladder just folds/flips up on top of the swim platform and I would like to add a ladder (4 step if possible) that stores under the new swim platform so it is out of the way when not in use.

As for bracing, that is where it gets tricky (for me anyway.) I could add two straight braces from the swim platform to the transom towards the center, away from the outdrive. But I am not sure how I would brace the side edges. I am not sure what they are called, but my boat has 2 compartments in the rear that stick out form the transom, thats where my batteries are installed. I don't think I would be able to run a straight brace from the swim platform to the transom itself. I could maybe run the braces from the platform to these 2 compartments though.

When it is all finished I would probably add something like Seadek to it.

I have searched online and haven't really found much info on doing something like this. Except for one other guy on this forum but he is working on a larger scale (and budget!) than I could do.