Superjet511

Seaman

- Joined

- Oct 22, 2018

- Messages

- 65

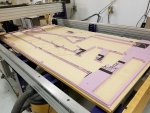

Back at it after a little hiatus due to the holidays and what not. Sorry for the delay. We got our interior back and it looks great; I love the carbon fiber look. I can't wait to get it into the boat. It gave me a little motivation to start getting the stringers done. Here are a couple of photos of the interior and the progress on the stringer removal. I found that a multi tool with a carbide blade works great and keeps dust to an absolute minimum. If I could only keep the blades from breaking. The teeth seem to last but the holes in the blade that mount to the base of the multi tool are getting worn so the blade quits oscillating once any pressure is applied. A couple of them also cracked....Does anyone have recommendations of brands that have been more durable? Now that I am back at it I will post more often.