- Joined

- Jul 18, 2011

- Messages

- 17,710

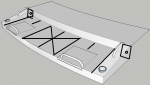

Ted, you could simply under-skin

I possibly could, except I'm not exactly sure what that means . . . Would it be creating a smooth 'skin' for the bottom of the platform as I am doing with the top side of the platform?

One of the challenges in the design has been providing enough tilt & turn room for the B3 outdrives. I had been figuring on fairly shallow (1-2") ribs front to back in order to provide rigidity to the platform, while allowing space for the extremes of outdrive movement. Perhaps more of a foam filled 'sandwich' would also work, instead of ribs. :noidea: