- Joined

- Jul 18, 2011

- Messages

- 17,692

Sunday Update (11/18/2018) . . .

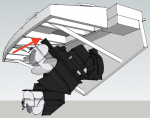

I got the fiberglass on the swim platform plug today. It took a while to glass all the corners and angles, but it is done.

Here are a few pics of the glassed plug . . . I colored the epoxy gray and added a filler to the epoxy to give it some body.

.

.

.

.

.

.

I'll need to do some fairing compound and sanding to get it smoothed out.

.

Here is a time lapse video of the glassing . . . 10 minutes of video covers about 1 hour. In total, it took about 3 hours to glass the plug.

I got the fiberglass on the swim platform plug today. It took a while to glass all the corners and angles, but it is done.

Here are a few pics of the glassed plug . . . I colored the epoxy gray and added a filler to the epoxy to give it some body.

.

.

..

.

.I'll need to do some fairing compound and sanding to get it smoothed out.

.

Here is a time lapse video of the glassing . . . 10 minutes of video covers about 1 hour. In total, it took about 3 hours to glass the plug.