Quick update . . .

I will be picking up the additional resin, some more DBM1708 and a small pour-in foam kit today.

I have been searching for a few better methods on wetting out large sheets (2' x 8' ) of the 1708 biaxial. In my past boat restoration work, I have used a large shallow pan for the resin and laid smaller pieces in the pan to soak. Working with larger pieces on this project has been more tricky to get the resin spread out evenly and soaking in on large (2' x 8') pieces.

A couple of methods that I have come across so far are to . . .

1) Lay the cloth out on the substrate, then fold half of it back on itself . . . wet out the half of the substrate and the half of the underside of the cloth that are exposed. Then fold the cloth back onto the substrate. Repeat for the other half.

2) Use polyethylene sheeting on a table . . . put the cloth face side down on the sheeting, pour the resin on the backside of half of the cloth. Fold the other half onto itself (sort of like booking wallpaper). Then put another polyethylene sheet over the cloth and use a rolling pin (or squeegee) to move the resin around.

I am wondering if there are some other 'tricks' that folks have used to wet out large pieces of biaxial :noidea:

Feel free to chime in. :thumb:

For this weekend, the plan is to . . .

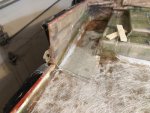

Put layer #2 of 1708 on the 'upper' deck, then secure the remaining foam core strips.

Use a bit of the pour-in foam around the perimeter of the foam strips to fill in gaps. I am getting 2 lb foam, and for the perimeter, I plan on pre-cooling the foam liquid parts so the I get less expansion and a higher density. We shall see how that goes.

Then I will trim up the cured foam and start on the outer layers of glass

Time permitting, I will work on some structural support in the 'pylon' areas and rear edge areas. I plan on boxing in some beveled areas on the underside that will be near the waterline. I'll use more of the pour-in foam to fill those structures.