Quick Update . . .

I'll be ordering more infusion supplies and the Formula color match gelcoat over the next few days.

I plan on using the 'Stretchelon 800' bagging film instead of the regular bagging film that I used for the mold infusion. The pleats and wrinkles in the bag trapped some resin, so the cured surface had all sorts of irregularities. The Stretchelon material strretches by about 4X which allows it to conform to the shapes of the mold without pleats or wrinkles.

Also need more peel ply and flow media.

I do have a life-time supply of TBC. . . PM me if interested.

Also, I found a source for Formula color matched gelcoat on the west coast. Not sure how well it will match the 22 year old gelcoat of the boat, but I figure it is better than using just a generic white color.

Looks like I'll be working on the platform most weekends in April-May. I got the 'Honey-Do' list whittled down a bit, having split my weekends over the winter being a carpenter/handyman one weekend, then a fiberglass fabricator the next

Game Plan looks like:

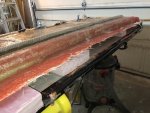

April 6-7: Pull mold from main plug, inspect mold, touch-up mold

April 13-14: Apply Gelcoat to molds (hatches & platform), layout initial glass layers, infuse molds.

April 19-21: Long weekend :thumb: . . . Layout core material, resin/glass in the core, layout outer glass layers, infuse outer glass layers.

April 27-28: Install rubrail backing and additional structural pieces

May 4-5: Pull platform from mold