froggy1150

Master Chief Petty Officer

- Joined

- Nov 3, 2017

- Messages

- 802

They have cheap ones at harbor freight if you have one of those near you

News Flash . . .

Other ideas?

Other ideas?

Sounds like my kind of luck. Dang that sucks - no pun intended

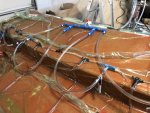

The vacuum pump I have ate some resin also. The new pump was thrown in the trash because the po was mad he did that. I fished it out, disassembled it and soaked it in acetone. Some bronze wool to clean it up and now it works perfectly.

There are times when I think if it weren't for bad luck, I would have any luck at all.

Ted, have you had a chance to pull the other pump apart? two pumps on-hand would aid in success in the event you suck up resin again

.

. .

.