scott011422

Cadet

- Joined

- Jan 15, 2018

- Messages

- 23

Hey all

My father and I purchased a 1997 24ft long Sylvan pontoon two years ago. It gets most of it use up on Lake Geneva in Wisconsin which can be quite wavy, especially on the weekends. So this year we decided we were going to add a third pontoon for more flotation and a better ride. I figured I would post everything up in case it could help someone with their conversion in the future.

This is the best photo I have of the boat. Since then, We have redone the seats, electrical, outboard, lighting, added a staircase to the trailer and started revamping the playpen skin.

IMAG0021 by scott011422, on Flickr

IMAG0021 by scott011422, on Flickr

Had the Donor toon delivered from Great Lakes Skipper. Its a Bemmington 25.5ft oval toon.

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

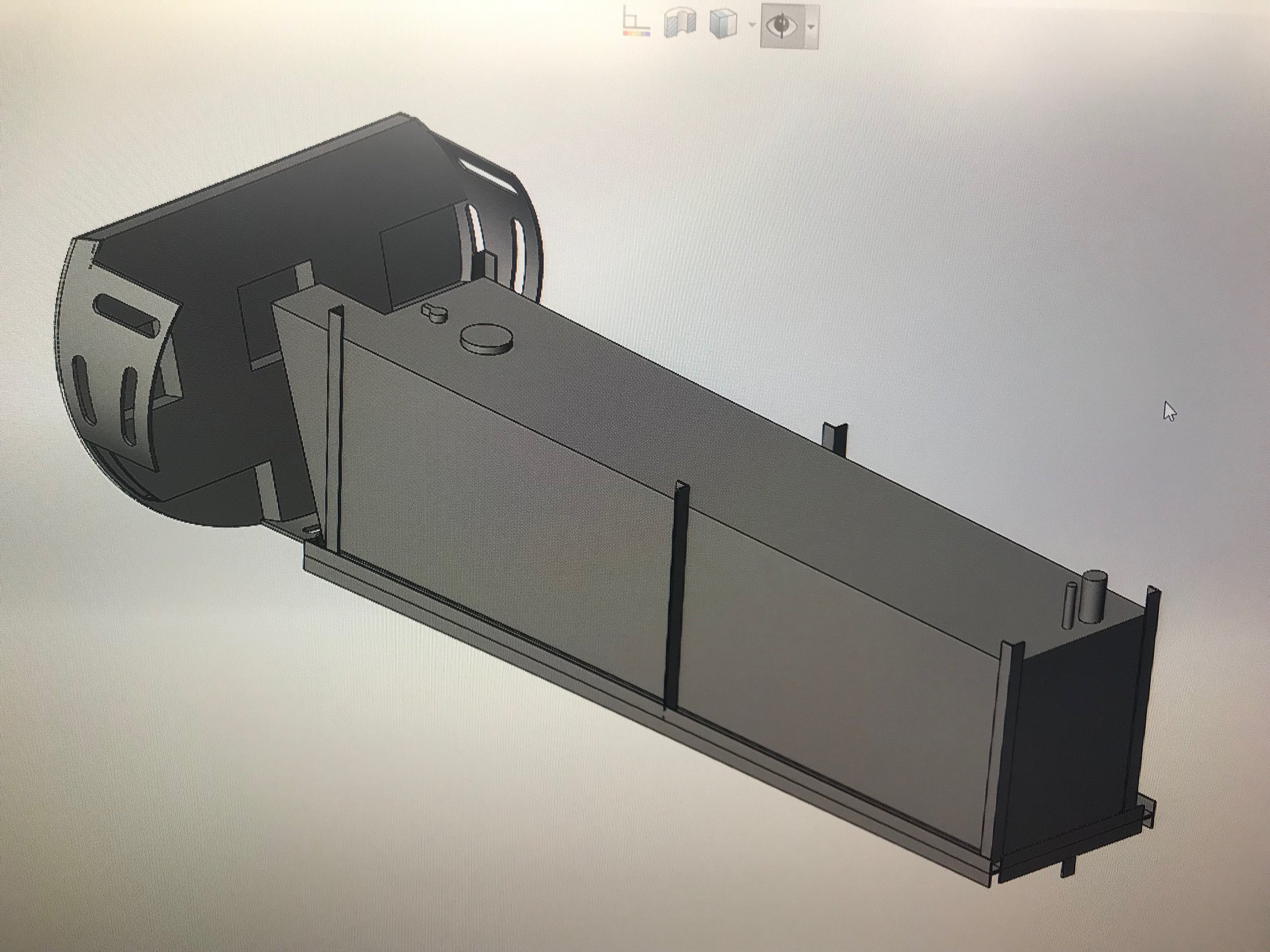

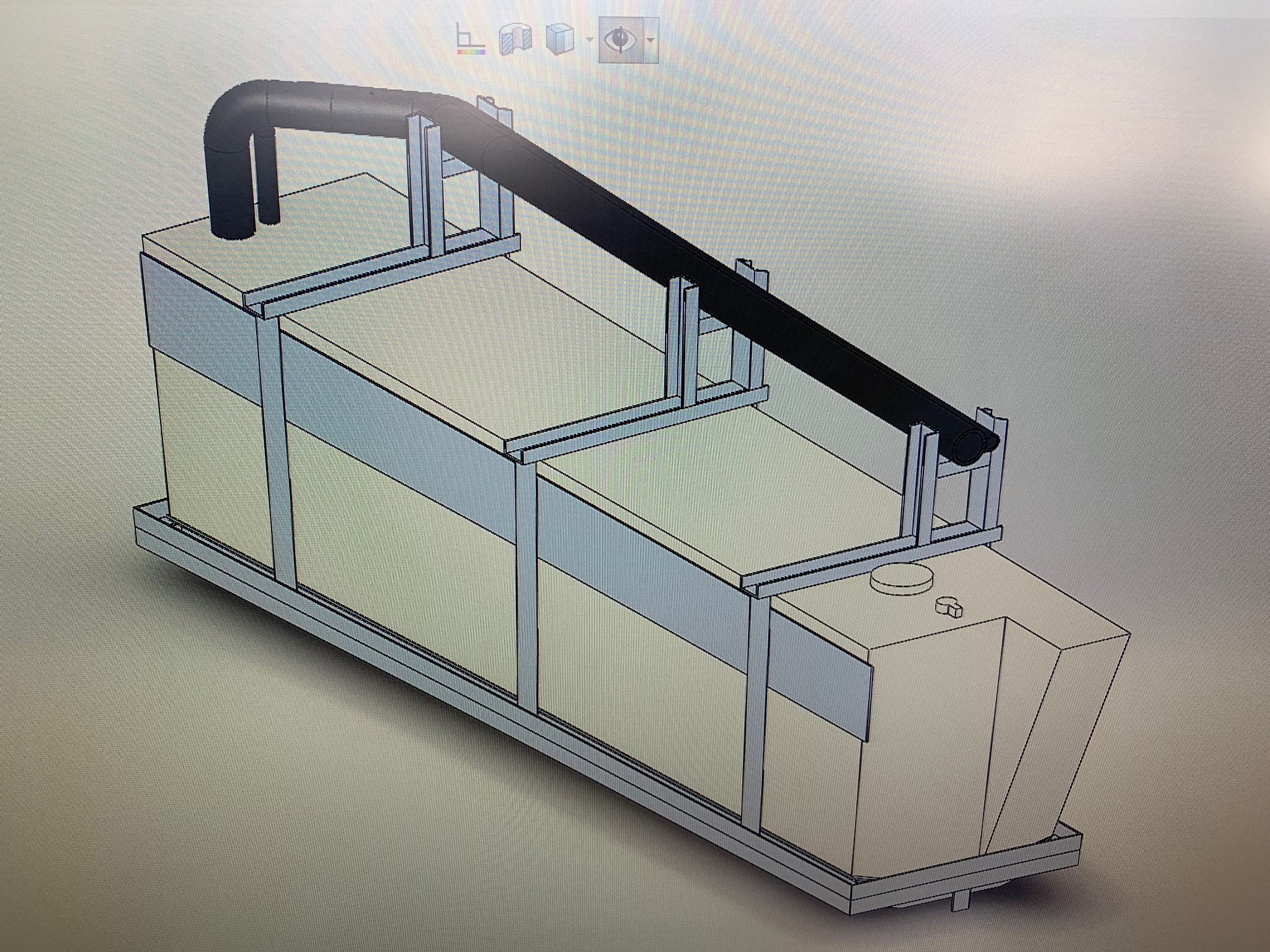

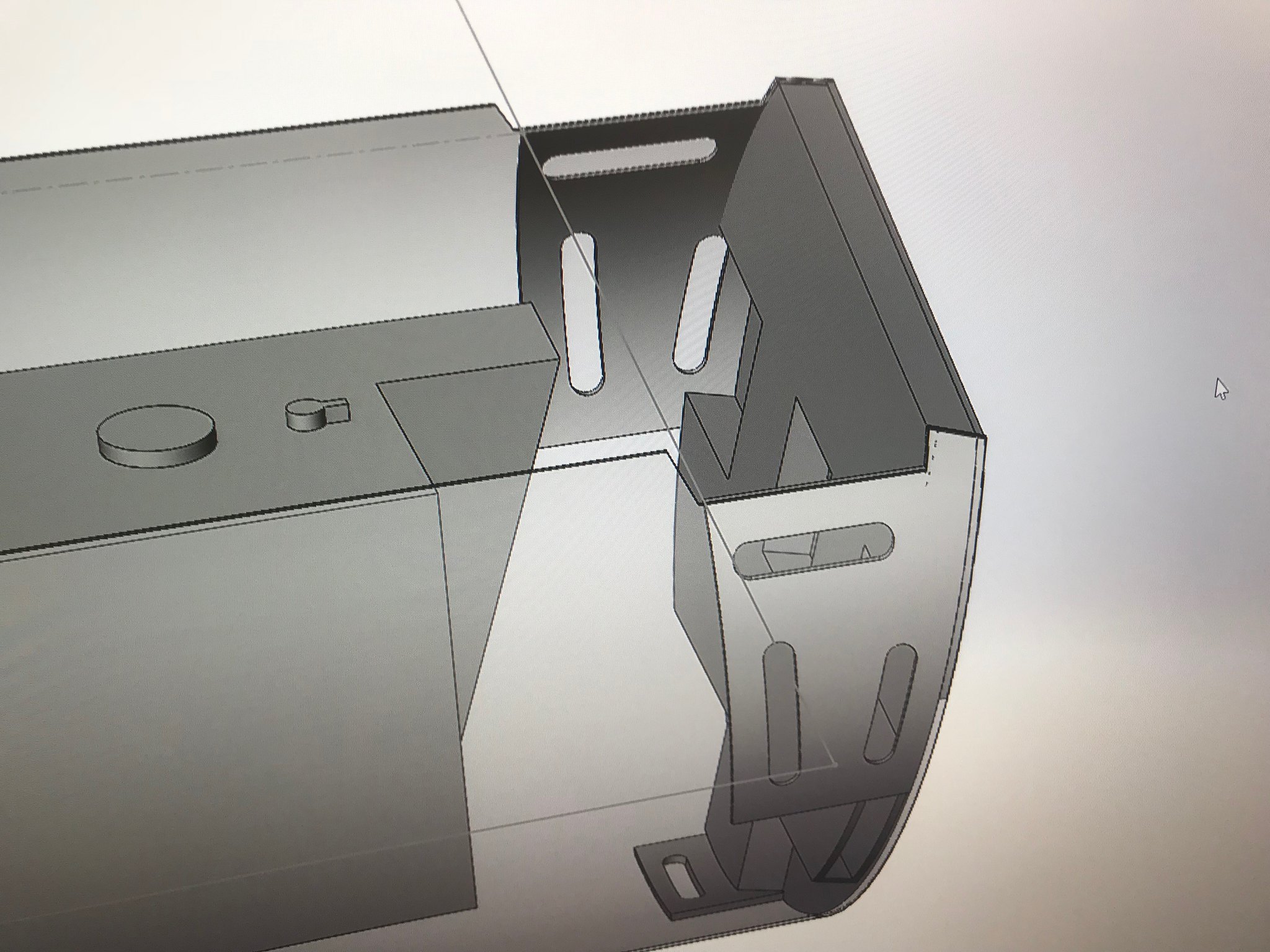

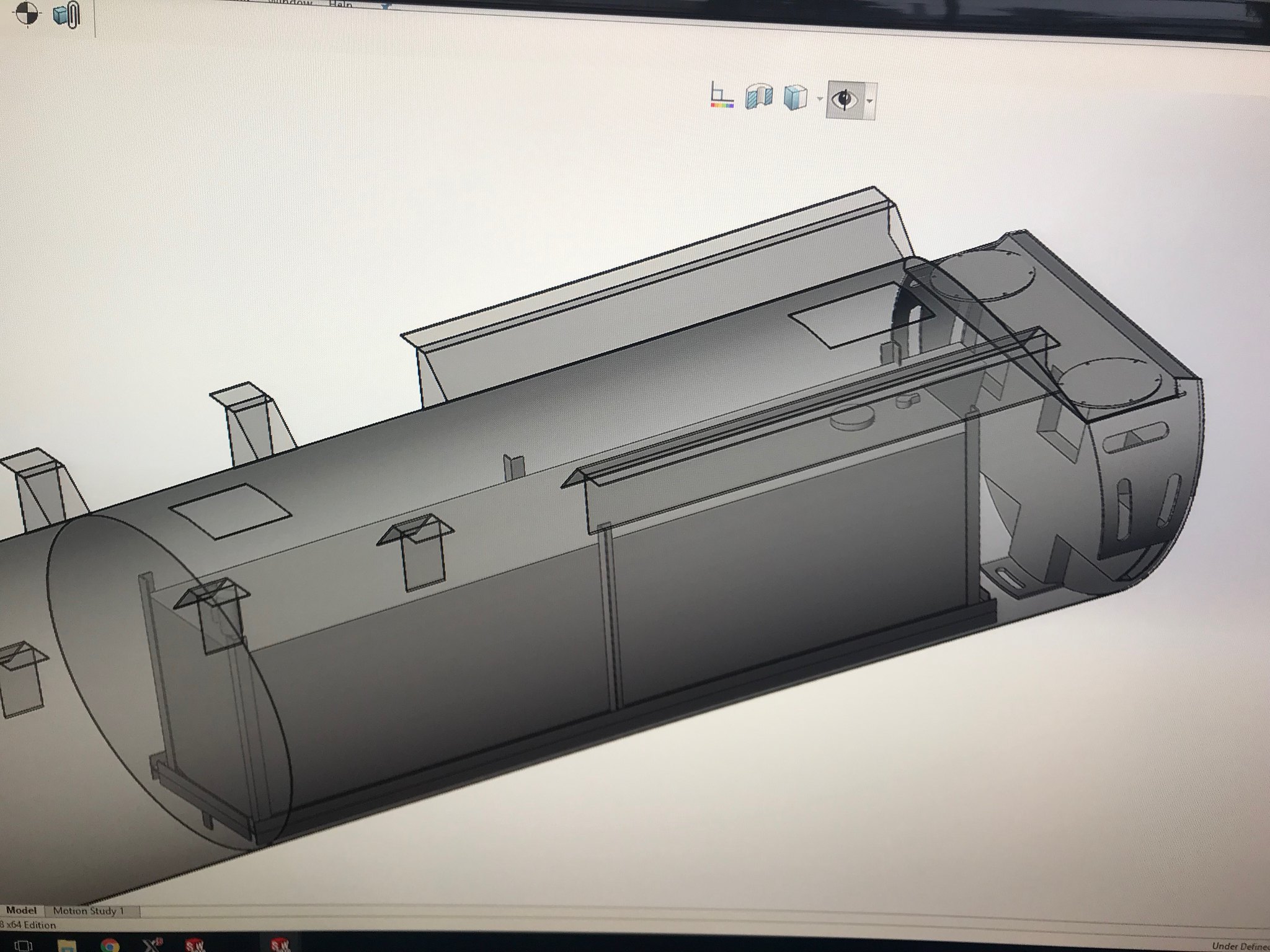

Untitled by scott011422, on Flickr

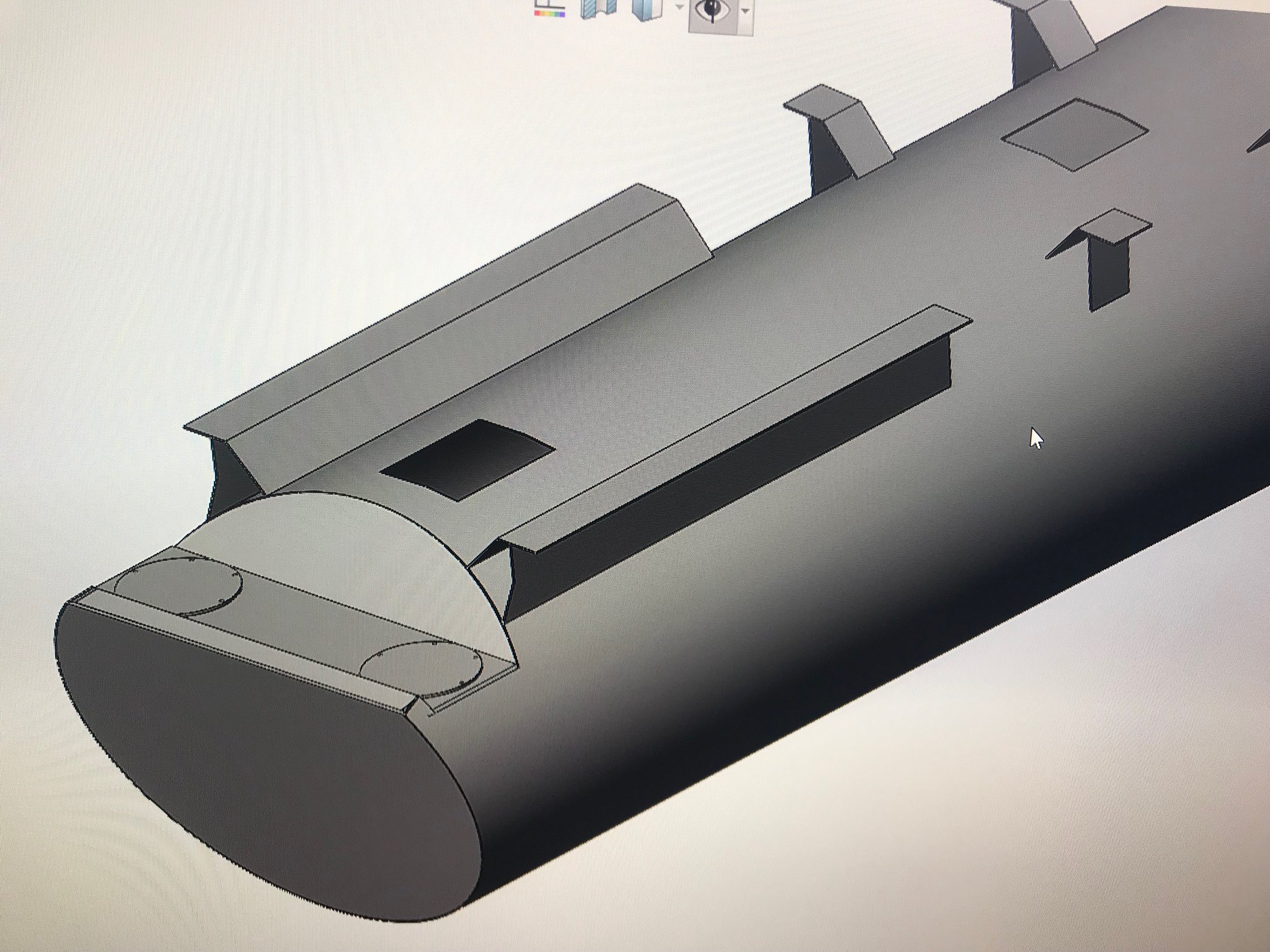

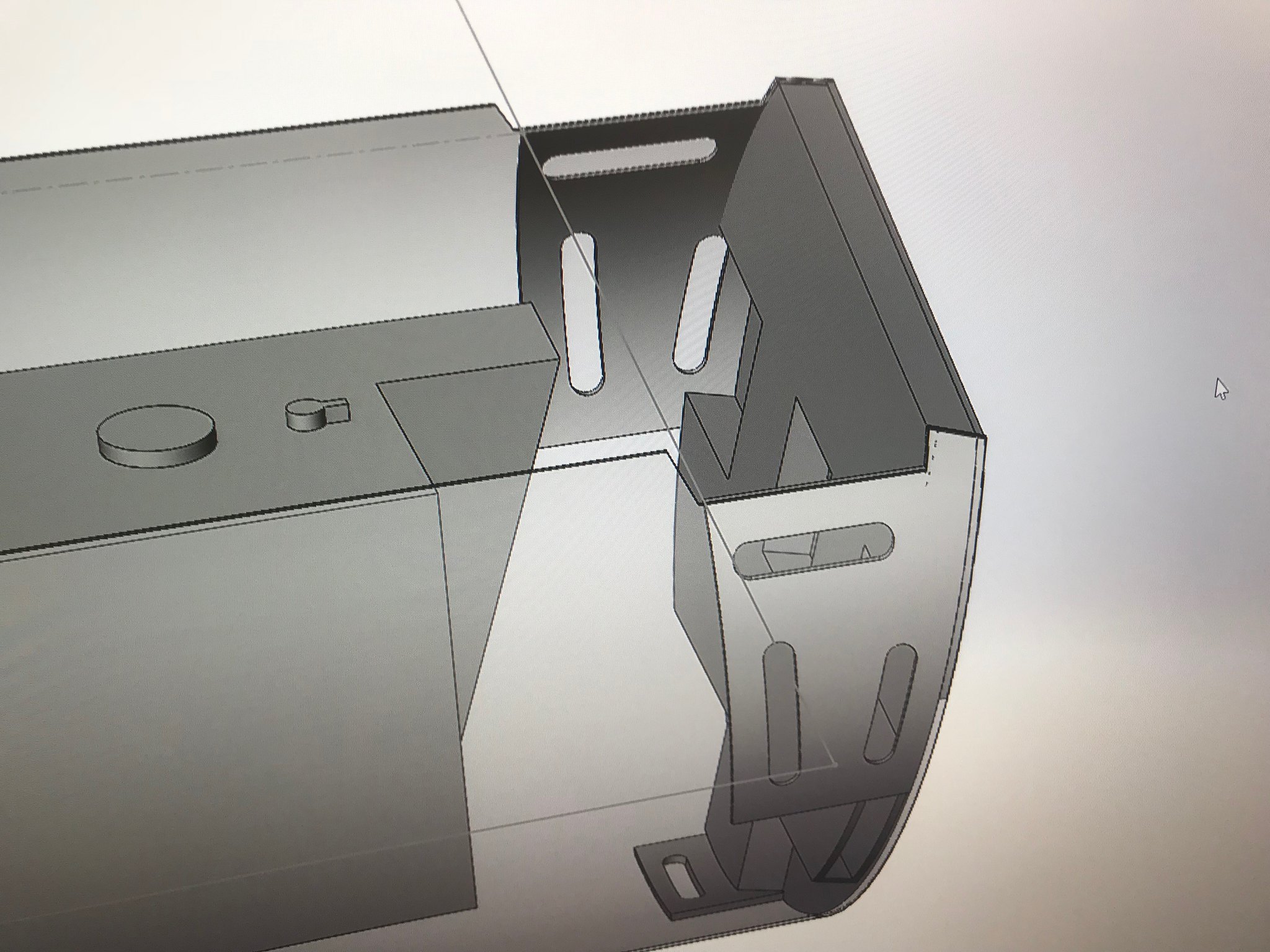

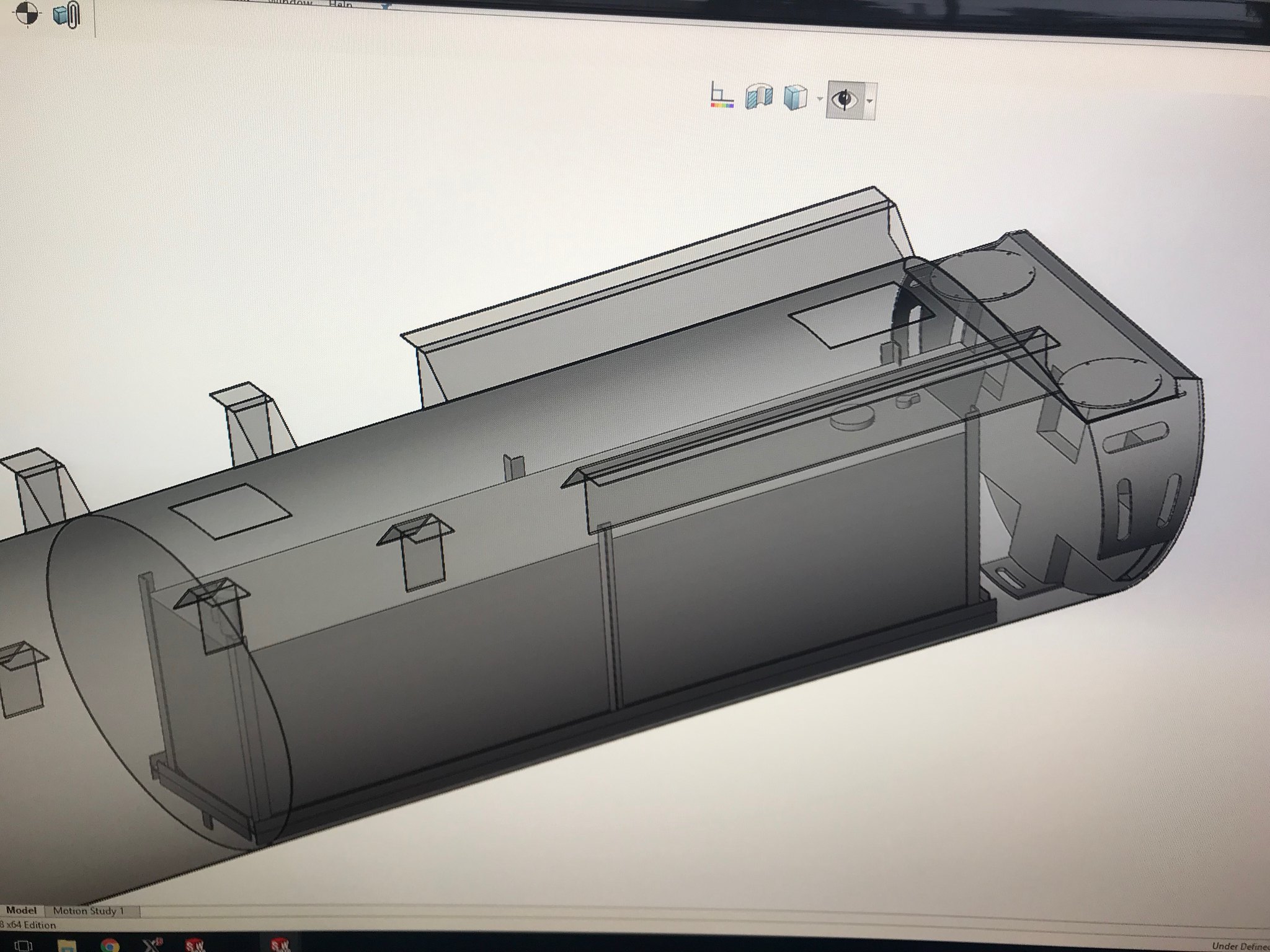

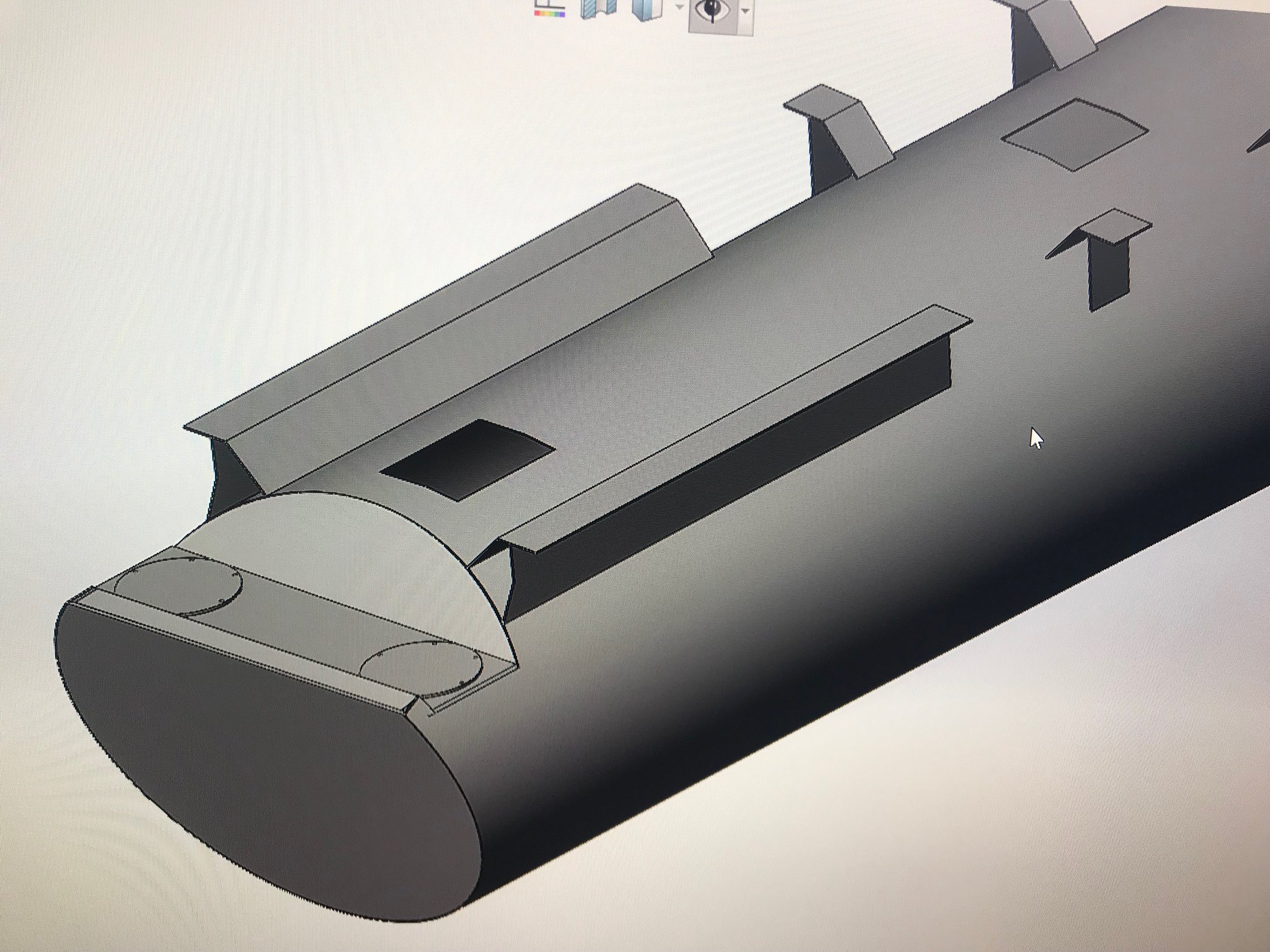

This toon is off a canceled special order. You can order any 2 toon boat with optional 32" oval logs. However, being its for a 2 toon boat, no integrated transom. So I purchased myself a TIG welder and am teaching myself to TIG Weld. Going to make my own transom. Since I'll be cutting off the back of the toon, its a good time to add a larger fuel tank too. We will be removing the factory 26 gallon tank off the deck which then gives us more storage space, and mounting a 49 gallon in the toon. To get the most out of this tool i am designing the transom to be 100% sealed for maximum flotation. All said and done, this should add roughly 1400 pounds of flotation on a normal outing with a maximum of 4000lbs when fully loaded. Here are my current designs:

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr

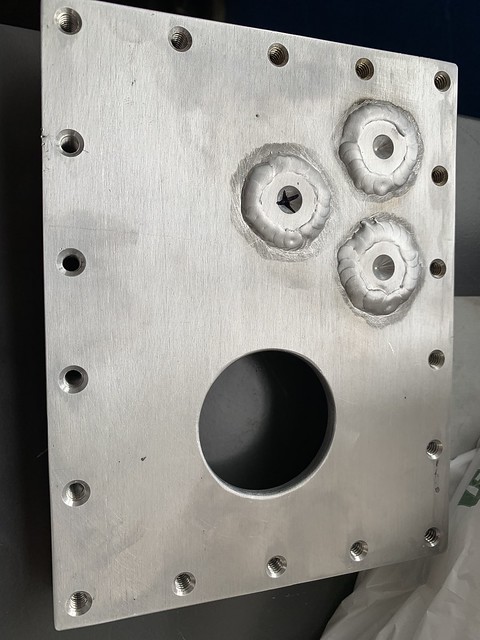

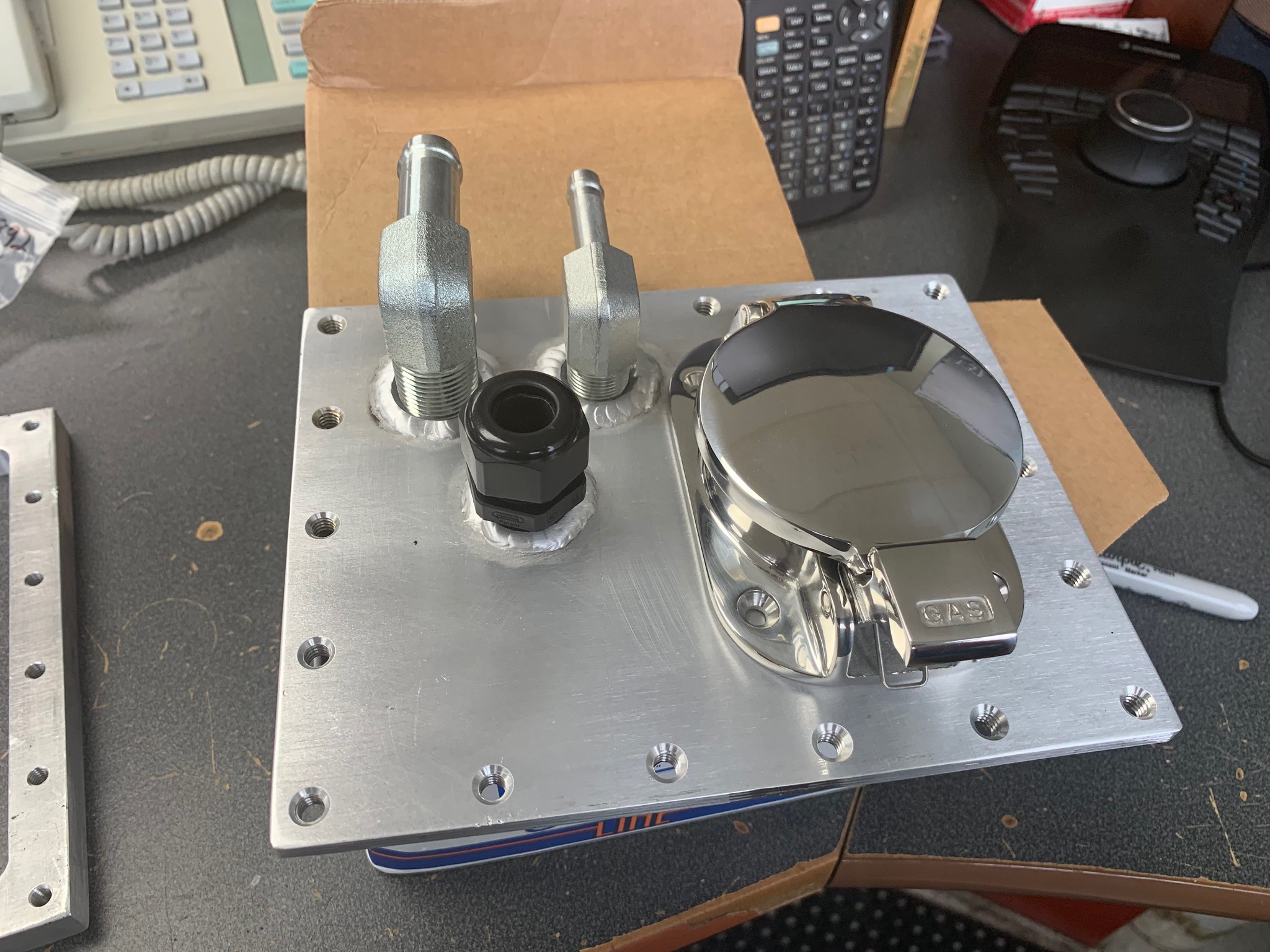

I will be using 3/16 Aluminum plate for the outer skin and 2"x 4" 1/4 wall tubing backing that up. I'll also have 3 1/4 thick plates that will be welded into the tubing and outer skin that will be welded onto the skin to help take up the stress from the outboard thrust.

My father and I purchased a 1997 24ft long Sylvan pontoon two years ago. It gets most of it use up on Lake Geneva in Wisconsin which can be quite wavy, especially on the weekends. So this year we decided we were going to add a third pontoon for more flotation and a better ride. I figured I would post everything up in case it could help someone with their conversion in the future.

This is the best photo I have of the boat. Since then, We have redone the seats, electrical, outboard, lighting, added a staircase to the trailer and started revamping the playpen skin.

Had the Donor toon delivered from Great Lakes Skipper. Its a Bemmington 25.5ft oval toon.

This toon is off a canceled special order. You can order any 2 toon boat with optional 32" oval logs. However, being its for a 2 toon boat, no integrated transom. So I purchased myself a TIG welder and am teaching myself to TIG Weld. Going to make my own transom. Since I'll be cutting off the back of the toon, its a good time to add a larger fuel tank too. We will be removing the factory 26 gallon tank off the deck which then gives us more storage space, and mounting a 49 gallon in the toon. To get the most out of this tool i am designing the transom to be 100% sealed for maximum flotation. All said and done, this should add roughly 1400 pounds of flotation on a normal outing with a maximum of 4000lbs when fully loaded. Here are my current designs:

Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr Untitled by scott011422, on Flickr

Untitled by scott011422, on Flickr Untitled by scott011422, on Flickr

Untitled by scott011422, on FlickrI will be using 3/16 Aluminum plate for the outer skin and 2"x 4" 1/4 wall tubing backing that up. I'll also have 3 1/4 thick plates that will be welded into the tubing and outer skin that will be welded onto the skin to help take up the stress from the outboard thrust.

Last edited: