Thanks

Baylinerchuck I'm very happy with the following I have had so far! Glad to have you here as well. I've seen your comments on other forums I follow on here and you really know your stuff as well. Although the progress seems quick, I have been idle for a week due to the job getting busy and I'm anxious to get back on it. But now I need to figure out which way I want to move forward, ply or dimensional.

Hoping to finish grinding and clean the garage tonight to get ready for the cutting the stringers and starting glass work. The debate in my head keeps going back and forth now that I have 100% of the pros on here recommending plywood rather than dimensional. Especially

89 resorter, who has an inboard, and used all ply. BAH

I did read that treated dimensional lumber is a bad idea for boat work. Once you glass it in there is no way for the gas/chemicals to escape; or something like that. If I was to do dimensional I would probably cut it, pre seal it with resin and put an initial layer of CSM on it for strength while the "seal" layer is still tacky. Kind of like how people have prepared their transoms before install.

A lot of my concern with the plywood is the fact that my bolts would be going into the end of the plywood. I know you can cap it with another piece and WOG makes it seem like if you soak the ends you'll end up with a strong board. But it concerns me.

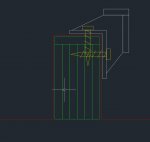

I definitely want to have the full 1 1/2" so that would end up being 3 layers of 1/2" so that I could sandwich one in the middle without creating a stress riser. Then in the motor areas I would have to do 6 layers to get to the full 3" (to replace the 2x). But with that I would be putting my lag bolt into the end of one or between 2 sheets. Below are rough sketches I made to illustrate my concerns, not perfect, but good for discussion.

looking at this gives me a bad feeling, I just don't feel like there is much strength in the side ends of plywood. I really want to take your guys' advice, since you are much more versed than I am, but it gives me an uneasy feeling.

In addition to all this, I also need to dig into the engine and get it running, but with the power out of the garage at the moment I am a little stuck. Was supposed to have an electrician over this week but that didn't work out.

and so off to looking for your guys' advice yet again. Sorry for the long response, I just want to try and spell out my thinking so that I can see if my thinking is in the right direction, or if I'm misinterpreting. so Please challenge my thinking or understanding, I have read a lot, and have an engineering mind for this stuff. but my experience in these departments is lacking.