froggy1150

Master Chief Petty Officer

- Joined

- Nov 3, 2017

- Messages

- 801

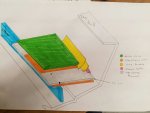

So here is the beginning of my journey. The sucky thing about this is the back of this boat was redone, had been in the water ONCE and then stored improperly. It doesn't seem that bad though. I have read back about 280 pages in the restoration forums on topics that either pertain or interest me so far. My first question is on the 3rd pic does the laminate seem thin. Its less than an 1/8th.

also looking for pics of one of these finished so I have an idea of the interior. Model rv2240

also looking for pics of one of these finished so I have an idea of the interior. Model rv2240

Attachments

Last edited by a moderator: