Hello guys

Long time no post, I'll try to catch up with what we have done since May,

we have been somehow busy, tired, under motivated... we are still doing one work session a week instead of 2 or 3 as we should. time to speed up as summer is already started and we would like to get on water this year.

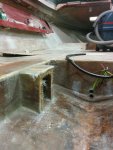

We have worked the engine mounts to re enforce them further by alternating CSM and biax as suggested. I believe they are fine now even tough some little air pockets are visible around the tight edges. They have been very difficult to work due to the shape of the parts and the lack of space.

We have also covered the seems of the different floor elements with biax tape before covering the whole floor with 2 layer of CSM. It was also a tricky job due to the surface to be covered and the amount of resin to be used as we wanted the 2 layers to be done wet on wet.

Here is how it looks afterward

The 2 layers of CSM also extend to the side of the hull on the top of the 2 existing 1708 tabbing.

hope it will be enough.