hatch project continues...

decided to go with these hinges

didn't here back from CP Performance regarding postage

mcmaster found it difficult with the idea of shipping down under

so left with good old ebay, shipped from USA, should arrive next week

https://www.cpperformance.com/p-13764-polished-stainless-steel-long-reach-hinges.aspx

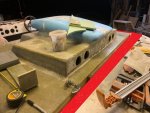

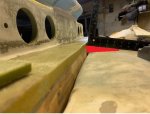

laminated the final gurit board+300grm CSM + 600 grm biaxle on to board, strength scoop inside started filling the 125mm extension, lots of grinding, glassing, grinding

attached pictures of selection of sanders used, purchased pencil grinder from depot/bunnings and proved to be quite successful with getting into tight spacers

needs a little more filling in scoop...but getting there

so now where to place engine hatch vents

Have hole saw cut the yellow 2* 3" holes for front of hatch (I intend to powder coat the vents so dont look at the colours)

refer photo 1 and 2

Not sure whether I should put the other twin hole vents down each side of the hatch, or alternatively place them at the back

looking for some help, ...is it best to place vents at rear or on side of hatch?

refer photos

Option 1: 2 rear vents with 2* 3" Dia holes, total: 4* 3" Dia holes

Option 2: no rear vents, use twin and single side hatch vents * 3" holes, in total 3* 3" holes

Option 3: 3 rear vents with 2 vents of 2* 3" Dia holes, and 1 vent * 3" holes, total: 5* 3" Dia holes

comments please

Picked up set of BBC Keith Eickert 2 piece valve covers with spring oils at weekend swap meet for budget price

nice

https://www.cpperformance.com/p-16736-big-block-chevy-2-piece-valve-covers-wvalve-spring-oilers.aspx