ASub

Seaman Apprentice

- Joined

- Oct 27, 2016

- Messages

- 33

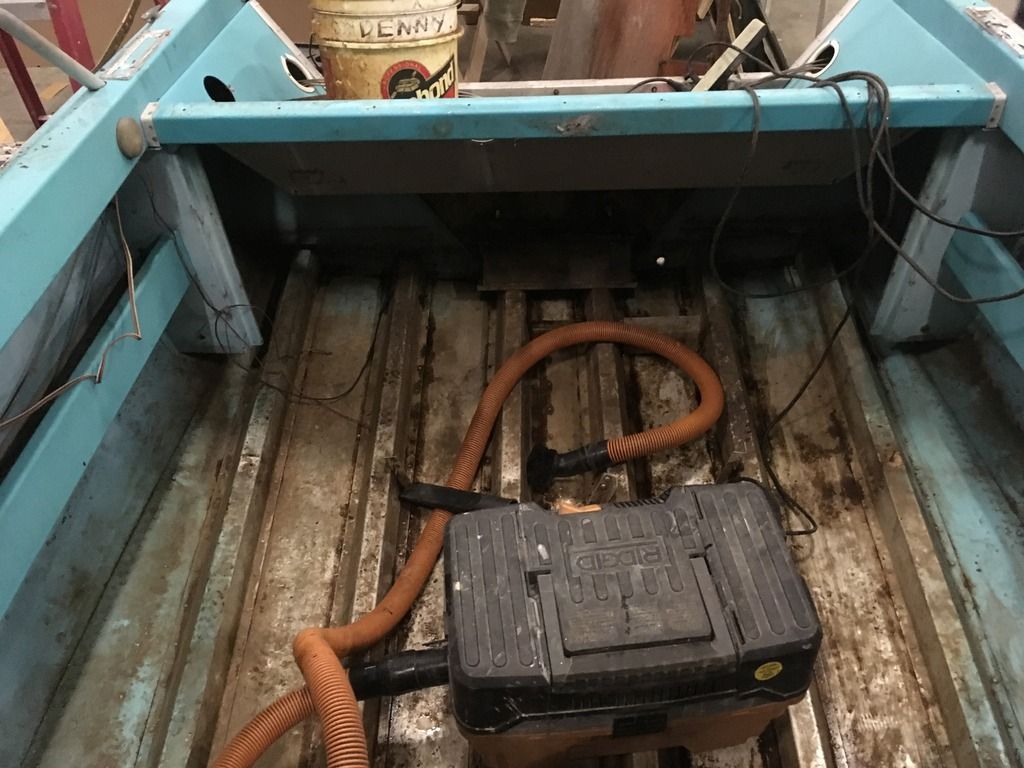

Hello All, I just bought up a 1965 Duratech Comanche off CL this week. It's currently on a trailer (probably original) that is sunk up to the axles meaning the first part of the project is the recovery. I will post photos of its current condition and location as soon as the forum allows me to post photos.

The boat is in very rough shape, but seems that most of the parts are there. I will be cleaning it up tomorrow to get ready to pull it out of its current spot.

I think this one had dual outboards on it from what I see. Does anyone have any info on this? I think it would be pretty wild to modern, dual power this boat. Thoughts on that are appreciated.

Is there any interest still out there on these boats? I saw it on CL and thought it was too cool of a project to pass up. Thanks in advance for any advice, photos and information about these boats.

ASub

The boat is in very rough shape, but seems that most of the parts are there. I will be cleaning it up tomorrow to get ready to pull it out of its current spot.

I think this one had dual outboards on it from what I see. Does anyone have any info on this? I think it would be pretty wild to modern, dual power this boat. Thoughts on that are appreciated.

Is there any interest still out there on these boats? I saw it on CL and thought it was too cool of a project to pass up. Thanks in advance for any advice, photos and information about these boats.

ASub