pekstrom

Chief Petty Officer

- Joined

- Dec 31, 2015

- Messages

- 490

No Title

Not sure how much longer I can wait. Although since the glue shouldn't be used below 55F I guess I don't have much choice...

Although since the glue shouldn't be used below 55F I guess I don't have much choice...

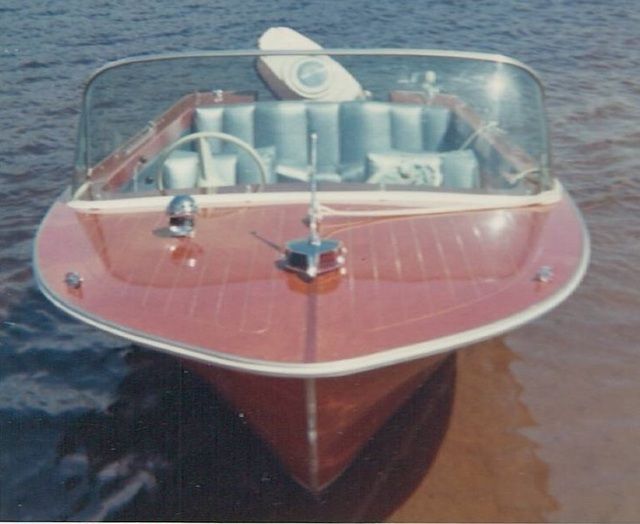

But, I did start putting things together this weekend to see how it all fits. And I also need to sand a lot of the parts I have so I think I will work on that. I attached a couple of pictures of the assebled parts I have, just in case anyone is curious.

Not sure how much longer I can wait.

But, I did start putting things together this weekend to see how it all fits. And I also need to sand a lot of the parts I have so I think I will work on that. I attached a couple of pictures of the assebled parts I have, just in case anyone is curious.