Hello everyone.

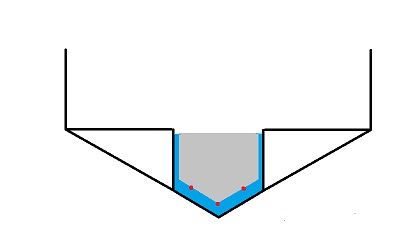

I started a thread here a while back, and never kept up with it. I am working slowly on removing my fuel tank as the baffles are shot, the one I can see through the sending unit hole looks like a brown carpet, and all its parts kept clogging my intake. Anyways they tank itself is made of 16 gauge SS and looks in great shape. Is it possible to have the top cut off, baffles replace, and top put back on? If so, anybody know where I can have that done. I want the tank to be USCG certified and know there are testings that must be done to a tank to make sure it is considered safe, so a shop that does that is what I'm looking for. Also, I would like to know of some places that make fuel tanks. If I replace with new tank, I will probably go with alum due to financial reasons. I live in Long Beach, CA. The tank is 140 gallons. It was made by IMCO. I'll work on pictures soon. Just trying to start lining everything up. If I have to have it re-made, I may consider making it slightly larger to get an extra 10-20 gallons, but I need to do calculations for that.

Thanks for any help, I know there is tons of info here.

Grady

I started a thread here a while back, and never kept up with it. I am working slowly on removing my fuel tank as the baffles are shot, the one I can see through the sending unit hole looks like a brown carpet, and all its parts kept clogging my intake. Anyways they tank itself is made of 16 gauge SS and looks in great shape. Is it possible to have the top cut off, baffles replace, and top put back on? If so, anybody know where I can have that done. I want the tank to be USCG certified and know there are testings that must be done to a tank to make sure it is considered safe, so a shop that does that is what I'm looking for. Also, I would like to know of some places that make fuel tanks. If I replace with new tank, I will probably go with alum due to financial reasons. I live in Long Beach, CA. The tank is 140 gallons. It was made by IMCO. I'll work on pictures soon. Just trying to start lining everything up. If I have to have it re-made, I may consider making it slightly larger to get an extra 10-20 gallons, but I need to do calculations for that.

Thanks for any help, I know there is tons of info here.

Grady