Greetings. First post here, but I've spent quite a bit of time reading through some of the various restoration projects. The last time I lifted my boat out of the water I noticed a crack in the hull that appeared to be deflecting outwards, not inwards, like it would have if I had hit something. I got the boat home and went after the crack with a grinder. After grinding through the hull, there was another section of fiberglass that was creating a hard point that the hull was flexing against and caused the crack.

It wasn't easy to get to the hole from above, so I had to do some removal in the bow storage compartments to get access to the hole. I found the hard point, but in the process I also found out a bit more about how the boat was constructed.

It turns out they used an upper liner than consisted of a fiberglass skin and the stringers. This was then glued to the hull to make a sort of composite hull. There is between 1/8" and 1/4" between the hull and liner and it looks like the adhesive used is delaminating from the liner and stringers. The stringers don't appear to be rotten, but when I cut into the liner, quite a bit of water was present between the two fiberglass skins.

Here's a shot of my boat. It's a modest 16' center console.

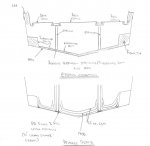

This is the layout of the bow area:

Here's a few shots of the starboard storage compartment

It wasn't easy to get to the hole from above, so I had to do some removal in the bow storage compartments to get access to the hole. I found the hard point, but in the process I also found out a bit more about how the boat was constructed.

It turns out they used an upper liner than consisted of a fiberglass skin and the stringers. This was then glued to the hull to make a sort of composite hull. There is between 1/8" and 1/4" between the hull and liner and it looks like the adhesive used is delaminating from the liner and stringers. The stringers don't appear to be rotten, but when I cut into the liner, quite a bit of water was present between the two fiberglass skins.

Here's a shot of my boat. It's a modest 16' center console.

This is the layout of the bow area:

Here's a few shots of the starboard storage compartment