Badfish95

Petty Officer 2nd Class

- Joined

- Jun 30, 2012

- Messages

- 118

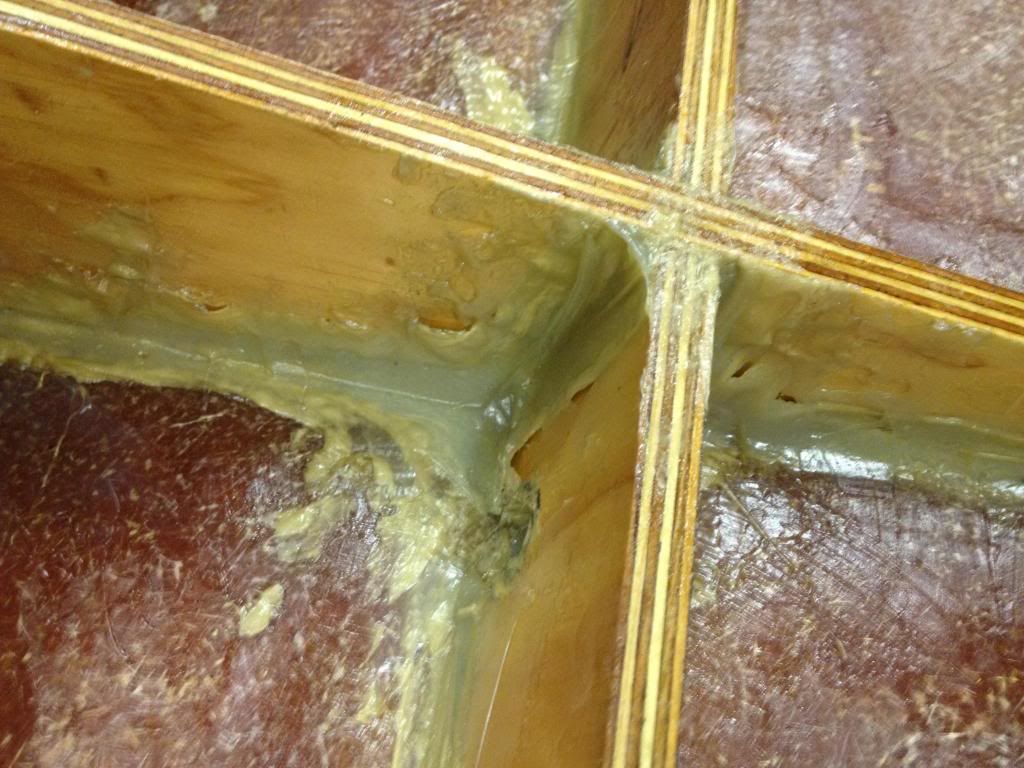

I was making great progress on my deck restoration until today. We decided to make up larger batches of Peanut Butter to expedite the fillet process. We used 2 Quarts of Polyester Resin and .9 oz of Mek(1.5%) per my calculations. We then added 2 quarts of Cabosil making it 1 to one. I used a paddle stirrer on a drill to make the mixing process easier. The working time was normal, but after 3 batches the intial applications started curling off!

WHAT HAPPENED!? I mixed it at 1.5% because the temp in the shed barely gets over 60 degrees. We let the PL bedding set for 48 hours. Before applying I wiped the stringers down with acetone to clean the dust and provide good adhesion. I did NOT use a wax or sanding agent on the intitial poly coating or the peanut butter.

Did I mix it too Hot?

Could the PL glue not be set?

My thought now is to let it cure fully, and cut or grind the cupped areas. I would use a little PB to fill the gap and then apply the 1708.

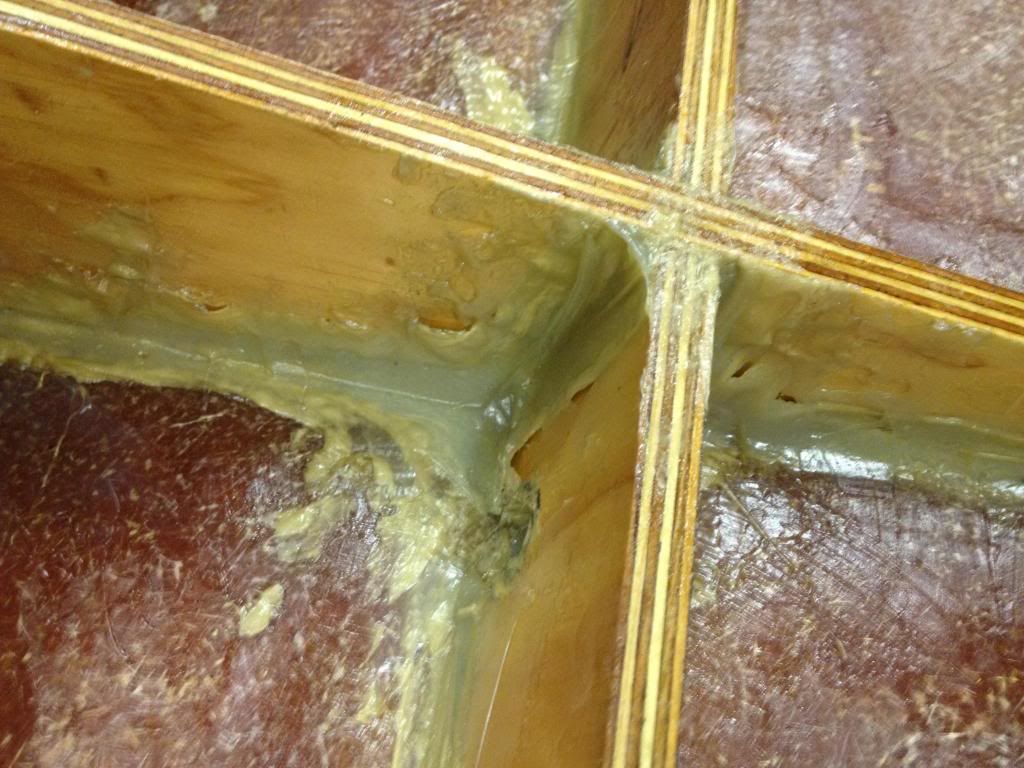

This photo shows the fillets I did on existing stingers a few days ago. The curled and cupped fillets are occuring on the new stringers that have been bed in with PL premium and resin coated 2 days ago without wax.

PLEASE HELP!

WHAT HAPPENED!? I mixed it at 1.5% because the temp in the shed barely gets over 60 degrees. We let the PL bedding set for 48 hours. Before applying I wiped the stringers down with acetone to clean the dust and provide good adhesion. I did NOT use a wax or sanding agent on the intitial poly coating or the peanut butter.

Did I mix it too Hot?

Could the PL glue not be set?

My thought now is to let it cure fully, and cut or grind the cupped areas. I would use a little PB to fill the gap and then apply the 1708.

This photo shows the fillets I did on existing stingers a few days ago. The curled and cupped fillets are occuring on the new stringers that have been bed in with PL premium and resin coated 2 days ago without wax.

PLEASE HELP!