Don Hansen

Petty Officer 1st Class

- Joined

- Sep 17, 2007

- Messages

- 230

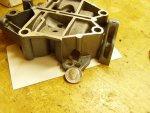

My 1974 4 hp threw a rod last, year putting a hole a little smaller than a dime in the crankcase wall. Here's what I'm planning on doing. I shaped a piece of 0.030 brass to cover the hole. After I clean and sandblast the crankcase I plan to glue the brass patch to the crankcase with J B Weld. Will that work? Did I missed something?

DLH

DLH