BillyOldBoat

Cadet

- Joined

- Aug 21, 2011

- Messages

- 13

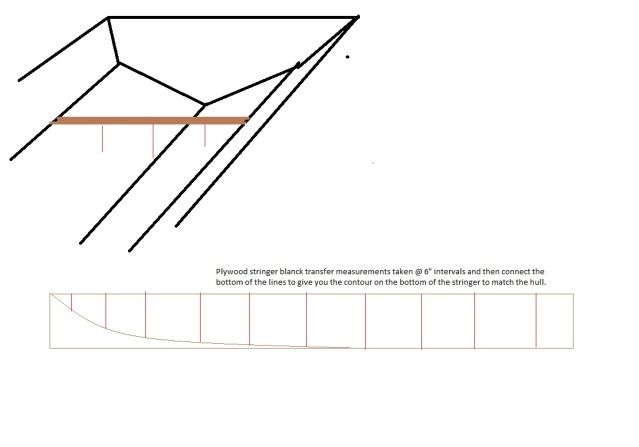

I hope someone can give me some advice. I am replacing the transom and stringers in a 1986 Starcraft Medalist 1901.

I have the stingers and transom out and am in the grinding phase.

The hull skin thickness of the transom is 1/4". I'm trying to figure out what thickness of plywood to use to rebuild it. In particular how much thickness does the fiberglass add. I was planning to glass it as such:

Hull + layer of 1.5 csm + wood + layer of 1.5 csm + layer of 1708 + layer of 1708. I think this is how Friscoboater did his.

Does this seem OK? And, what thickness of plywood should I use? Is there a list somewhere that tells you the thickness of cured fiberglass layer for the different types/sizes of fiberglass? I thought I saw one awhile back, but can not find it for the life of me now.

Also, when installing the stringers, should they butt up against the transom and be tabbed in, or should there be a layer of PL or peanut butter between stinger and transom as their is between stinger and hull?

Many thanks for any help you can provide.

I have the stingers and transom out and am in the grinding phase.

The hull skin thickness of the transom is 1/4". I'm trying to figure out what thickness of plywood to use to rebuild it. In particular how much thickness does the fiberglass add. I was planning to glass it as such:

Hull + layer of 1.5 csm + wood + layer of 1.5 csm + layer of 1708 + layer of 1708. I think this is how Friscoboater did his.

Does this seem OK? And, what thickness of plywood should I use? Is there a list somewhere that tells you the thickness of cured fiberglass layer for the different types/sizes of fiberglass? I thought I saw one awhile back, but can not find it for the life of me now.

Also, when installing the stringers, should they butt up against the transom and be tabbed in, or should there be a layer of PL or peanut butter between stinger and transom as their is between stinger and hull?

Many thanks for any help you can provide.