Re: PVC Exterior Trim Boards - Has Anyone Used This Material Before???

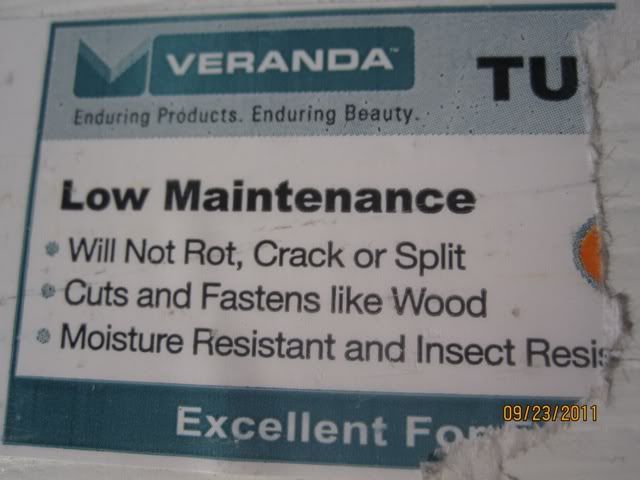

I have used a composite wood product that I think may be similar to what you have seen. The product that I used was an accessory trim piece for composite deck planking material. It is very heavy compared to wood and it has poor structural strength for its weight, so I don't think it's suitable material for building a "floor" in a boat. I experimented before using it, trying to stain it with motor oil, etc and it seemed pretty much impervious. It is soft, so it could be scratched or abraded. However, it has a woodgrain finish that if damaged, can be resurfaced easily in a few minutes with a wire brush.

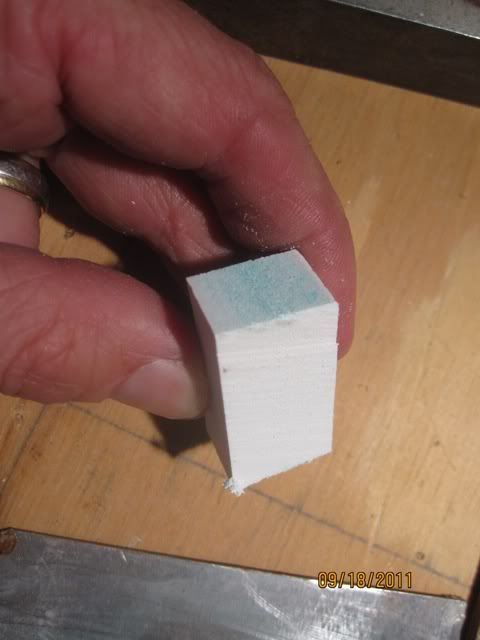

The trim material that I used had about a 1-1/2" cross-section and was 6 feet long, intended to be an end cap for thicker composite deck planks. The material's extruded thickness was only about 1/4". Where I found it useful was as a replacement for the original vinyl walkway on my 1972 21' Starcraft Holiday aluminum on both the fore and stern decks. I cut the "legs" of the U-shape off in a table saw, leaving strips 1/4" thick by 1-1/2" wide that I glued to the sanded aluminum with PL Premium. It looks as good today as when I installed it about 10 years ago. It looks just like wood, even changing to a darker color when it gets wet and lightening again as it dries. It's easy to machine. You can actually chisel it easier than wood, more like hard clay since it has no grain to split. - Grandad