Hi everyone. I have a 1984 Carver Mariner 28 that had a 20" wide swim platform on the transom. The platform was soft, the core was rotten, and it was not large enough for our uses (dinghy storage and general boarding). Here is a photo of where I started:

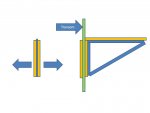

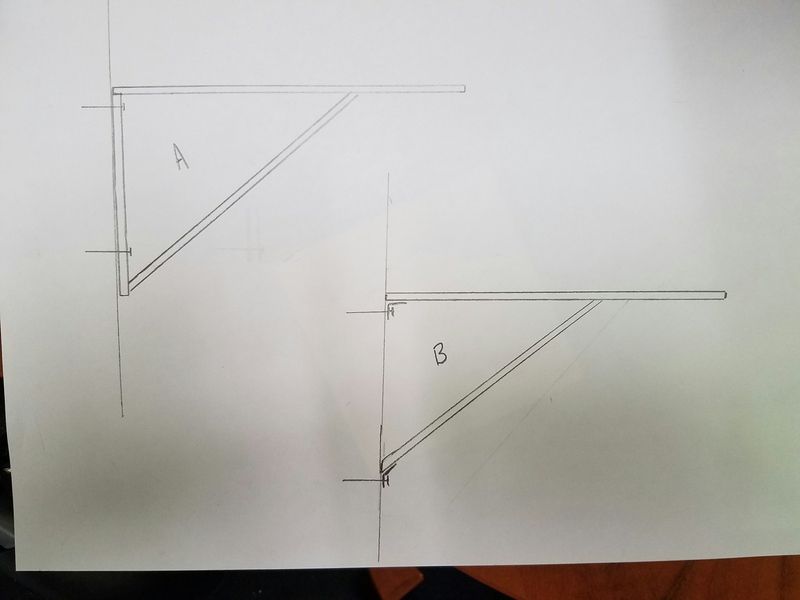

Here is a sketch of the supports I plan to install, a total of 5 that will through bolt to the transom with large backing plates on the inside:

The question I have right now is, which method is stronger? There is a lot of stress on the upper bolt and transom using method A. I am wondering if I should go to method B, as I feel more pressure would be transferred through the diagonal.

Any thoughts?

Here is the framing for the supports mocked up.

Stainless steel framing and fittings. Will be using starboard on top and around the perimeter to give it some depth.

On paper this seemed a solid approach, I am just wondering what your thoughts all are. The 5 supports will have bracing going between them to provide support for the starboard. This will extend 36" out vs the old 20" platform.

Here is a sketch of the supports I plan to install, a total of 5 that will through bolt to the transom with large backing plates on the inside:

The question I have right now is, which method is stronger? There is a lot of stress on the upper bolt and transom using method A. I am wondering if I should go to method B, as I feel more pressure would be transferred through the diagonal.

Any thoughts?

Here is the framing for the supports mocked up.

Stainless steel framing and fittings. Will be using starboard on top and around the perimeter to give it some depth.

On paper this seemed a solid approach, I am just wondering what your thoughts all are. The 5 supports will have bracing going between them to provide support for the starboard. This will extend 36" out vs the old 20" platform.