I have a mid 70's Merc 115 with NO tilt or trim. I posted some time about hitting mud and my cabin being in low water. Used tilt and trim for this motor is $300 - $500 and parts hard to find and expensive when repair needed. The CMC thing used is $500. Tried to sell the boat to buy something with tilt and trim. No luck. So, figured I'ld see if I could make my own.

This will ONLY be used at idle to get to my dock.

A & B are original shock mount posts.

Point "C" is a cantilever point.

Point "D" is new mounting point.

Steering is NOT interferred with

Using 3/4 x 1.5 solid aluminum

Plan 1 - If I were to mount and Automotive air shock to "A" and "D" and a used automotive leveling pump or small 12 v air compressor to raise and lower unit. Cost about $100

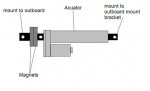

Plan 2 - A pair of 12v Linear Actuator on "A" and "D" Cost $300

http://www.amazon.com/Northern-Indu...ie=UTF8&s=miscellaneous&qid=1254150113&sr=8-6

Plan 3 - Getting a used Convertible top setup. Cost $100

COMMENTS ????

This will ONLY be used at idle to get to my dock.

A & B are original shock mount posts.

Point "C" is a cantilever point.

Point "D" is new mounting point.

Steering is NOT interferred with

Using 3/4 x 1.5 solid aluminum

Plan 1 - If I were to mount and Automotive air shock to "A" and "D" and a used automotive leveling pump or small 12 v air compressor to raise and lower unit. Cost about $100

Plan 2 - A pair of 12v Linear Actuator on "A" and "D" Cost $300

http://www.amazon.com/Northern-Indu...ie=UTF8&s=miscellaneous&qid=1254150113&sr=8-6

Plan 3 - Getting a used Convertible top setup. Cost $100

COMMENTS ????