fire7882

Petty Officer 2nd Class

- Joined

- Jul 15, 2008

- Messages

- 172

This is a little long but I thought I would include as much info as possible. I think there is some head gasket installation confusion that prevents proper cooling of the lower starboard cylinder on Evinrude/Johnson V4 powerheads. My service manual(Clymer. Yea, I know) doesn't give very detailed head installation instructions so I thought I would throw this out there as well as ask a few question. I just got into boating and I've acquired 3 90 hp v4 motors in the process of trying to get one good one and all three had problems with the lower starboard cylinder.

I just got finished assembling the block I have been working on in this thread.Block Damage Thread Since this block has had its problems, I have been checking and rechecking everything as I go along. I stopped by the marine parts store today and grabbed a couple head gaskets so I could go ahead and finish things up. I'm now having trouble deciding how these thing are installed. I have 2 new, never installed Mallory 9-63828 head gaskets(replaces jonny/rude # 318358) and one new but previously installed Sierra 18-2956 (also replaces jonny/rude # 318358). This powerhead is from a 1988 90 hp V4, model # E90TLCCA.

The first gasket is a Mallory with the thin side of the metal ring facing up. The second is the other Mallory with the wide side of the metal ring facing up. The last one is the Sierra with the wide side up. All gaskets are the same symmetrically.

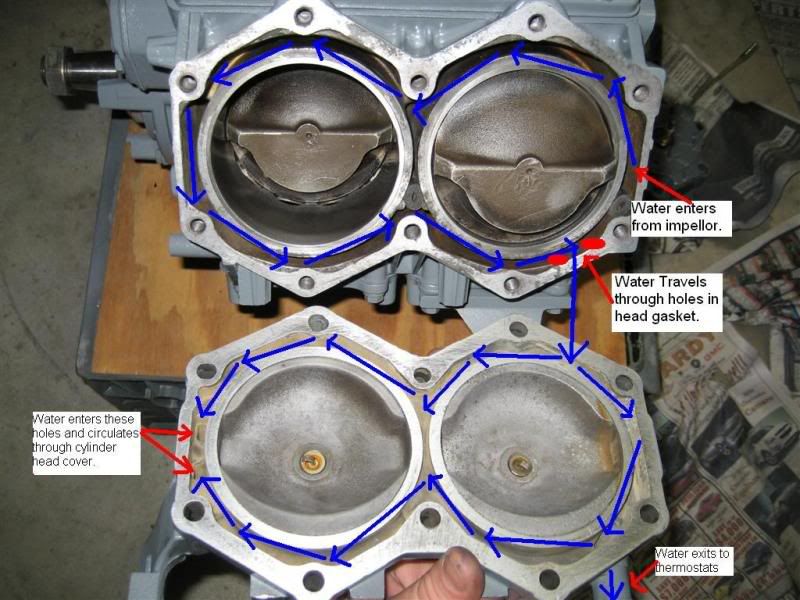

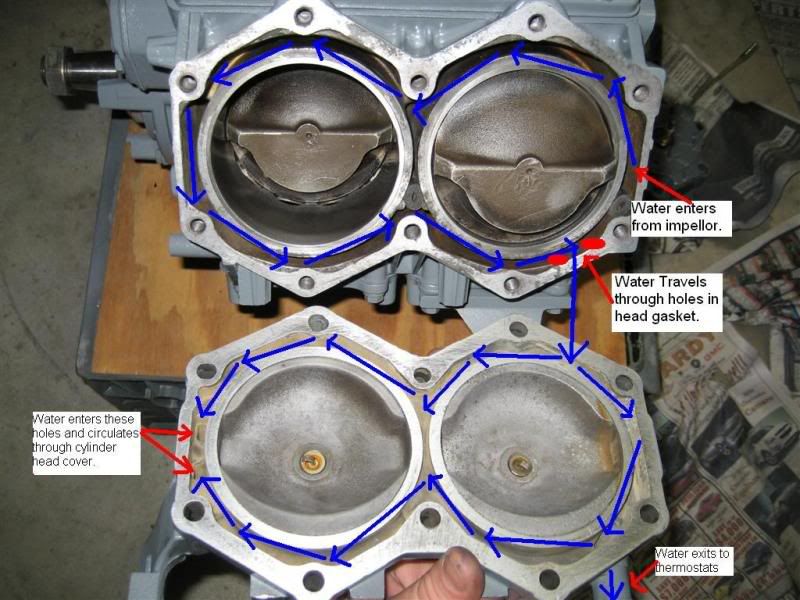

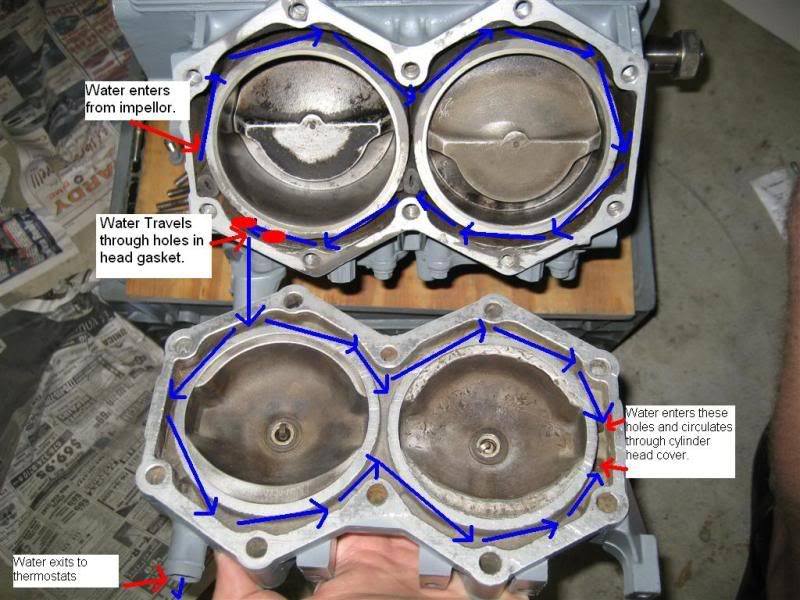

Below are a few pictures showing how I think the water should flow through both the port and starboard side of the engine. First I'll discuss the port side.

This is how I believe the flow of water should travel through the head.

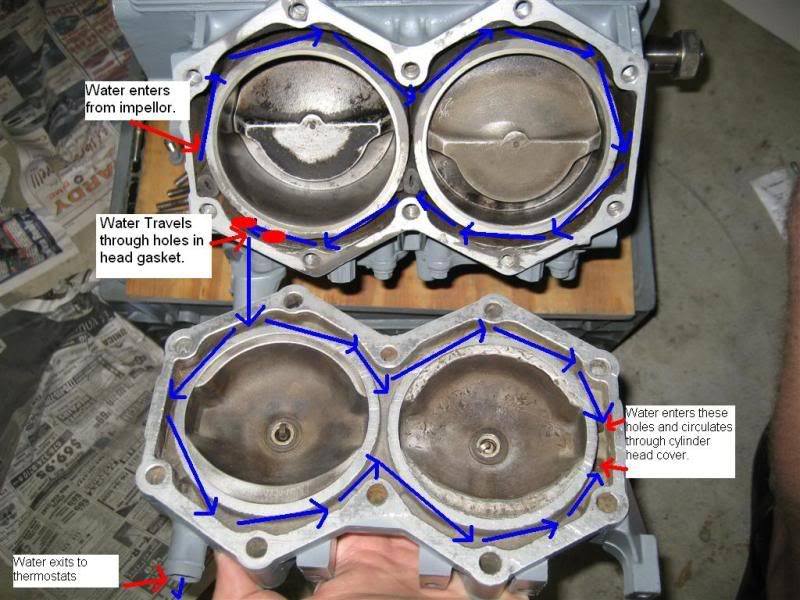

This is how the head gasket would need to be installed for the holes to end up in the correct location. The notation on the tab of the head gasket (left side in this picture) reads "Top, Arrow to Exhaust cover" You can see this wording in the picture of all the gaskets. I assume top means the top side of the block and not facing up toward the head. Also. notice that the metal cylinder sealing ring has the thin side contacting the Head.

Now, on the starboard side, I believe the water should flow like this.

With the holes in the proper location, the wide band is now facing up. The gasket is also installed properly according to the notation on the tab.

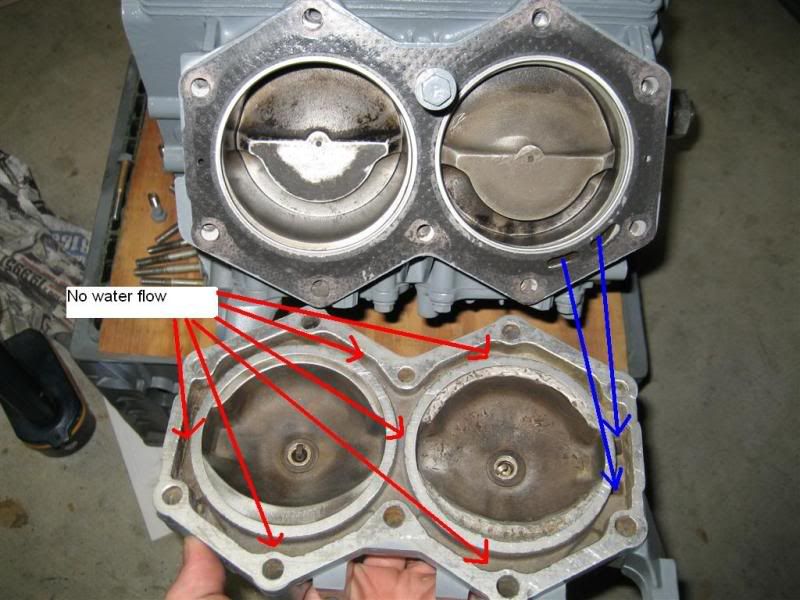

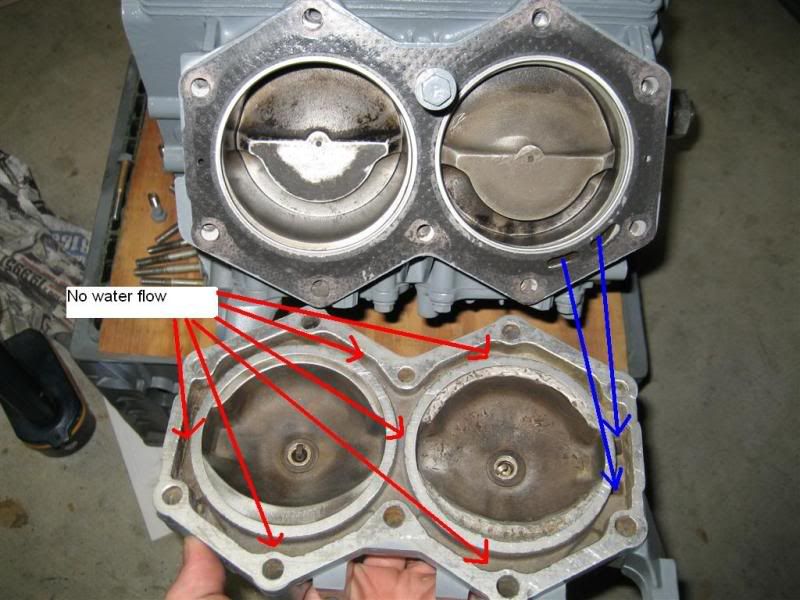

If you put the thin band up like the other side, the holes position would prevent the lower cylinder from getting proper cooling. As you can see, water would also bypass most all of the passages in the head before it reached the cylinder head cover. Here you can also see that this upper cylinder also suffered some damage.

The Mallory gaskets I bought today didn't have any kind of installation notes on them like the Sierra gasket did. I would think this could cause some confusion to someone who hasn't worked on these motors before(like me). It wouldn't be hard to assume that the similar sides of each gasket should be making contact with the same surface, either head or cylinder.

Now a couple questions.

Does it matter which side of the metal sealing ring makes contact with the head? I assume it doesn't and the most important thing is to have the water passages in the correct place.

Have my assumption be correct? Any advice, suggestions, or additional info?

I just got finished assembling the block I have been working on in this thread.Block Damage Thread Since this block has had its problems, I have been checking and rechecking everything as I go along. I stopped by the marine parts store today and grabbed a couple head gaskets so I could go ahead and finish things up. I'm now having trouble deciding how these thing are installed. I have 2 new, never installed Mallory 9-63828 head gaskets(replaces jonny/rude # 318358) and one new but previously installed Sierra 18-2956 (also replaces jonny/rude # 318358). This powerhead is from a 1988 90 hp V4, model # E90TLCCA.

The first gasket is a Mallory with the thin side of the metal ring facing up. The second is the other Mallory with the wide side of the metal ring facing up. The last one is the Sierra with the wide side up. All gaskets are the same symmetrically.

Below are a few pictures showing how I think the water should flow through both the port and starboard side of the engine. First I'll discuss the port side.

This is how I believe the flow of water should travel through the head.

This is how the head gasket would need to be installed for the holes to end up in the correct location. The notation on the tab of the head gasket (left side in this picture) reads "Top, Arrow to Exhaust cover" You can see this wording in the picture of all the gaskets. I assume top means the top side of the block and not facing up toward the head. Also. notice that the metal cylinder sealing ring has the thin side contacting the Head.

Now, on the starboard side, I believe the water should flow like this.

With the holes in the proper location, the wide band is now facing up. The gasket is also installed properly according to the notation on the tab.

If you put the thin band up like the other side, the holes position would prevent the lower cylinder from getting proper cooling. As you can see, water would also bypass most all of the passages in the head before it reached the cylinder head cover. Here you can also see that this upper cylinder also suffered some damage.

The Mallory gaskets I bought today didn't have any kind of installation notes on them like the Sierra gasket did. I would think this could cause some confusion to someone who hasn't worked on these motors before(like me). It wouldn't be hard to assume that the similar sides of each gasket should be making contact with the same surface, either head or cylinder.

Now a couple questions.

Does it matter which side of the metal sealing ring makes contact with the head? I assume it doesn't and the most important thing is to have the water passages in the correct place.

Have my assumption be correct? Any advice, suggestions, or additional info?