Re: Mounting motor to boat.

Since you do not have any way to thru bolt the motor, another option you may want to consider...

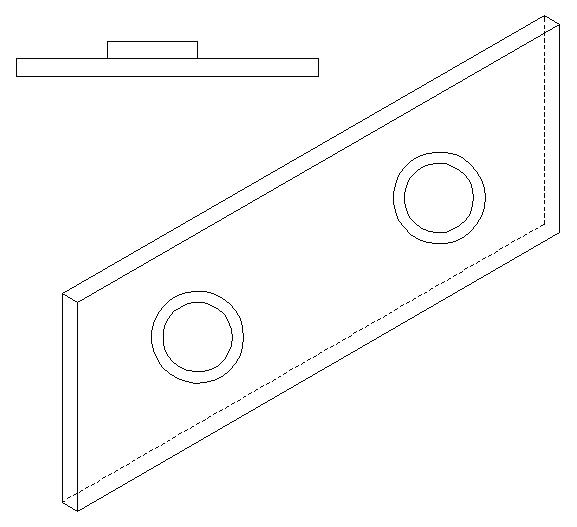

Had an old 66 merc 9.8hp that was always wanting to walk up the transom... so I had fabricated a special plate for the transom... basically, it was a thin aluminum plate (1/8" thick).. on the plate I had them weld two circles of raised 1/4" aluminum, that were slightly larger than the flat plates for the set screws for the motor...

Set your motor on, position the plate so that it lines up under the motor screws, tighten up the motor screws, then thru bolt the plate itself. This completely solved the problem, as it was near impossible for the motor mount screws to "jump" out of the inside of 1/4" deep dishes.

total fabrication cost was around 50 bucks including materials.

Sorry its really hard to explain... I did a very rough drawing for you (and my drawing skills suck, so I apologize):

The top picture shows you how the "circles" were raised higher than the rest of the plate.

The bottom one kinda shows the plate itself, your motor mount screws would set into the middle of those "rings" where they couldnt move up or down.

Hope that helps!