fabrimacator21

Petty Officer 1st Class

- Joined

- Jun 28, 2009

- Messages

- 286

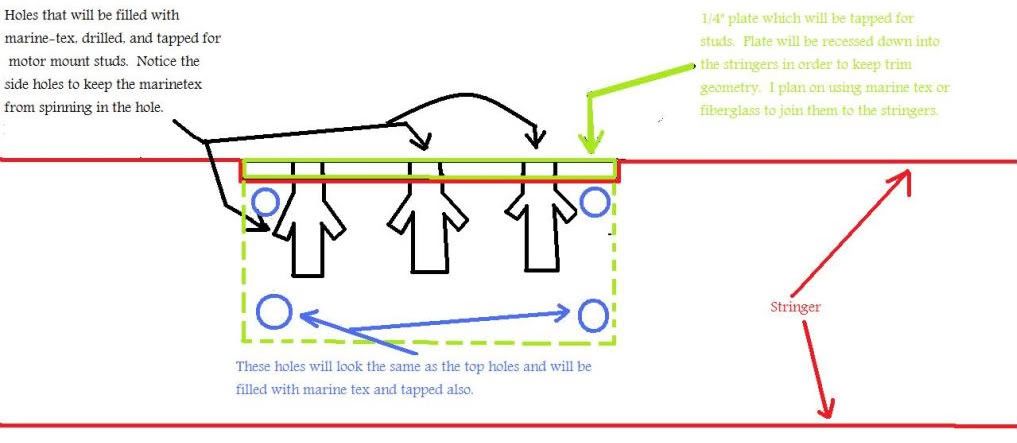

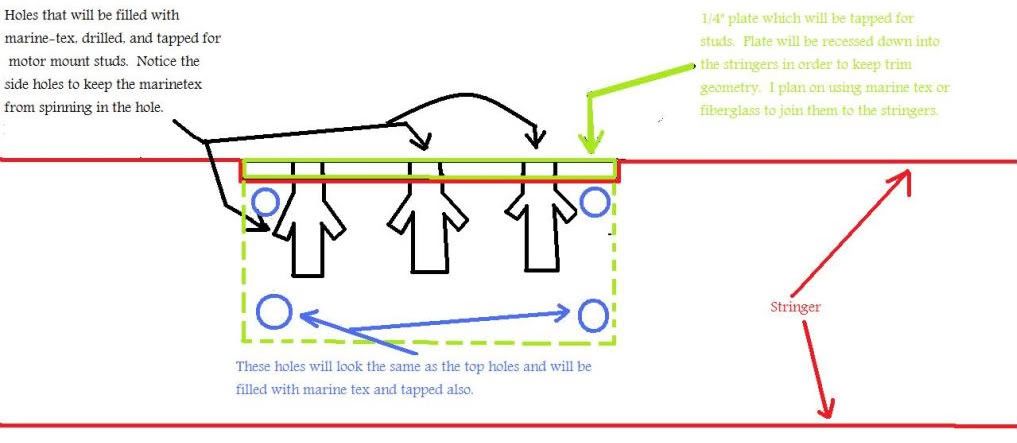

The motor (305 chevy small block/ OMC 200hp) is currently mounted to the stringers by six bolts in the front and six bolts in the back. (3 on each corner of the motor). It has studs that screw into the stringers but they are pulling out and won't tighten down so here is what I came up with. Keep in mind that the plate will be an "L" bracket that will tie into the stringer on the side and top. The black holes would be the top and the blue holes would be the side(of the stringer). Sorry for the crude paint drawing.

Any thoughts?

I don't think the stringers are bad... the wood isn't moist or rotted, just old and the holes are stripped out. I just put a new floor and carpet in the boat so I REALLY don't want to put new stringers in it.

Any thoughts?

I don't think the stringers are bad... the wood isn't moist or rotted, just old and the holes are stripped out. I just put a new floor and carpet in the boat so I REALLY don't want to put new stringers in it.