Saskatoon2005

Master Chief Petty Officer

- Joined

- Apr 27, 2005

- Messages

- 810

Here is my drawings for my stringer designs: I don't know if you can read my writing so I will spell it here....

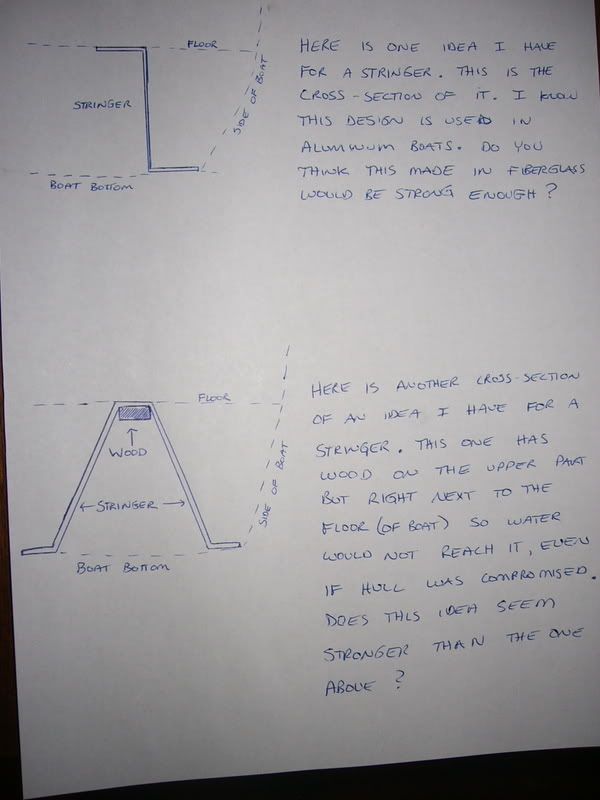

The first picture (upper left corner) says, here is one idea I have for a stringer. This is the cross section of it. I know this design is used in aluminum boats. Do you think this made in fiberglass would be strong enough?

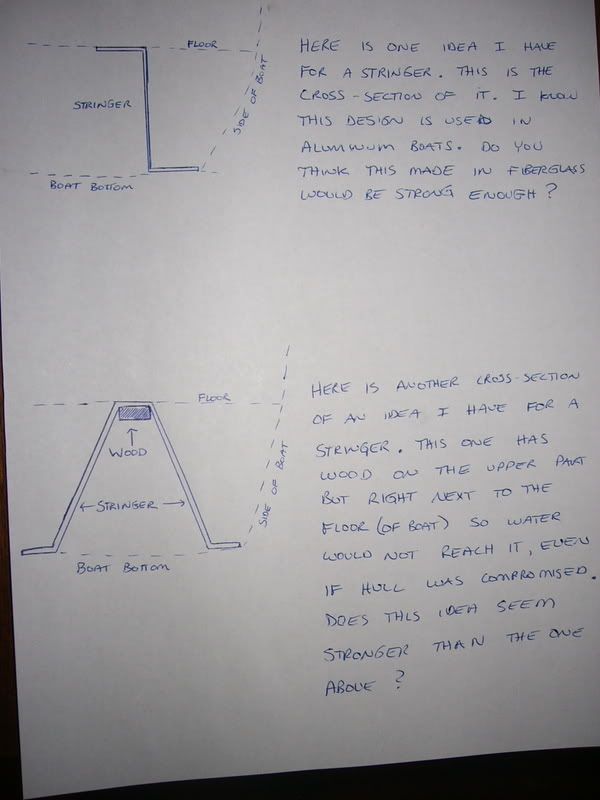

The second picture (lower left corner) says, here is another cross section of an idea I have for a stringer. This one has wood on the upper part but but right next to the floor (of boat) so water would not reach it, even if the hull was compromised. Does this seem stronger than the one above?

The first picture (upper left corner) says, here is one idea I have for a stringer. This is the cross section of it. I know this design is used in aluminum boats. Do you think this made in fiberglass would be strong enough?

The second picture (lower left corner) says, here is another cross section of an idea I have for a stringer. This one has wood on the upper part but but right next to the floor (of boat) so water would not reach it, even if the hull was compromised. Does this seem stronger than the one above?